Pharmaceutial Solution Filling Capping Machine

DESCRIPTION:

The Solution Filling Capping Machine for Pharmaceutical applications, a specialized solution designed to automate the filling and capping process of various liquid pharmaceutical products. This advanced machine is specifically tailored for the pharmaceutical industry, offering a seamless and efficient solution for filling and capping bottles or vials with liquid solutions such as syrups, oral medications, eye drops, and more.

The Solution Filling Capping Machine incorporates a range of features to ensure accuracy, precision, and compliance with pharmaceutical standards:

FEATURE:

1. Diving type: Servo System

2. 1 to 12 heads filling pump stations according to the speed required.

3. Piston pump, Ceramic pump, and peristaltic pump as optional

4. Application for different sizes and shapes of bottles by changing parts

5. Various speed settings of liquid filling.

6. Easy to Clean and fast Changeover

7. High filling accuracy which can meet ±0.5% to ±1%.

8. Simple and quick tech mode setup.

9. Track full / track empty sensors tell the machine to stop or re-start

10. Bottle mouth holder design for special applications

11. Siemens PLC control with user-friendly operation, Touchscreen Display, and Easy to Navigate Menu

12. Motorized single-lane sanitary conveyor. customized conveyor lengths are available upon request.

13. Type 304 stainless steel bin, frame, enclosure panels.

14. Type 316L stainless steel contact parts.

15. Calculates and Displays the Production Rate (Bottles/Minute)

16. Saves and Stores Filling Programs for Future Use

17. Contamination Free Filling - Only the inside of the filling tube contacts the liquid. Ideal for high purity applications

SPECIFICATION:

|

1 |

Model |

RVF |

|

2 |

Brand |

RELIANCE |

|

3 |

Automatic Grade |

Fully Automatic Solution Filling Capping Machine |

|

4 |

Drive Type |

All Servo Drive |

|

5 |

Industry |

Cosmetic, Pharmaceutical, HealthCare |

|

6 |

Application |

Liquid, Oil, Gel, Cream, Body Care, Solution, Suspension, Oral Liquid, Energy Shot, CBD Drink, Probiotic Liuiqd, Cough Syrup. |

|

7 |

Powder |

3.5 KW 110V/Single Phase or 220V 3 Phase |

|

8 |

Air pressure |

0.4-0.8Mpa 25 – 35 L/Min |

|

9 |

Container |

10ML, 15ML, 20ML, 30ML, 50ML, 60ML, 75ML, 125ML, 250ML Glass or Plastic Bottle |

|

10 |

Filling System |

Piston Pump, Volumetric Pump, Gear Pump |

|

11 |

Filling Accuracy |

± 0.5 – 1 % |

|

12 |

Capacity |

35 – 100 bottles/min |

|

13 |

Function |

Filling, Caps sorting, caps pick up and place on, cap close, finish |

|

14 |

Core Parts |

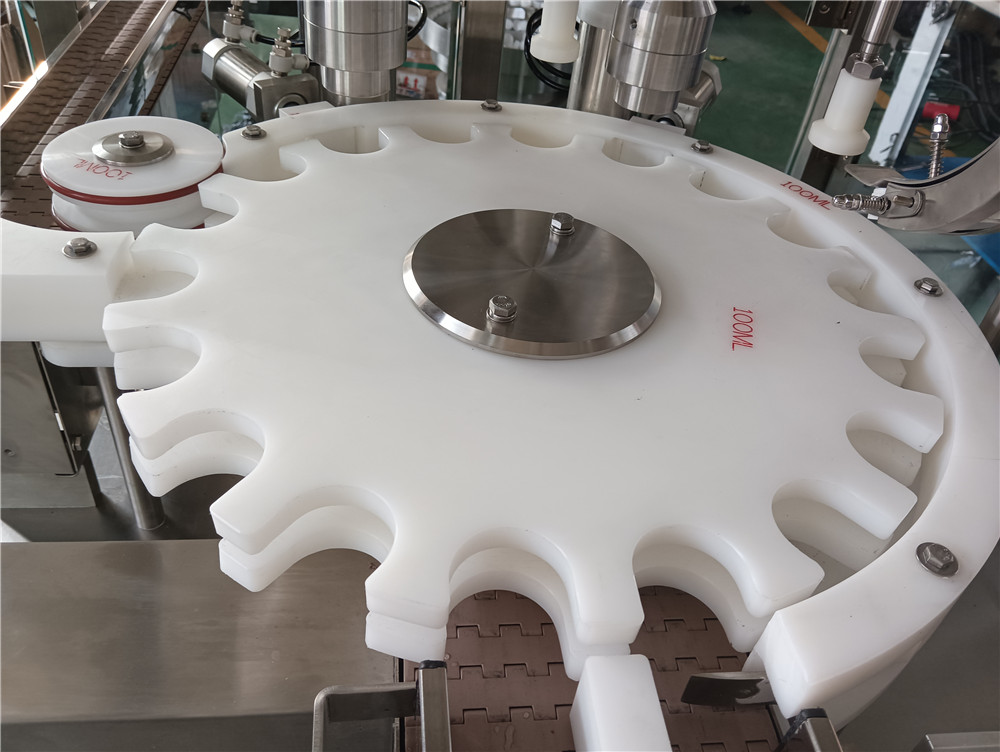

Frame, Table, Dosing Pump, Filling Nozzles, Vibration Hopper, PLC, Touch Screen, Sensor, Rejection, Alarm, Safe Door, Star Wheel, Robot Arm. |

|

15 |

Documents |

IQ, OQ, PQ, FAT, SAT, Operation Manual |

|

16 |

Dimension |

2400 x 1500 x 1750 mm ( L X W X H) |

|

17 |

Weight |

750 KG - 1200KG |

|

18 |

Relative Machine |

Feeding Table, Mixing Tank, Labeling Machine, Shrink Machine, Cartoner Machine, Check Weight. |

OPTIONAL:

1. Liquid buffer/storage tanks.

2. Bottle buffering table

3. Safe door

4. Bottleneck holders

5. Rinser station before filling system station

6. Anti-drip filling nozzles for oils

7. Rejection station

8. Piston pump, Ceramic pump, and peristaltic pump as optional

Types Of Solution-Filling Capping Machines:

There are several types of pharmaceutical solution filling capping machines available, each designed to cater to different production requirements and bottle/vial specifications. Here are some common types:

1. Automatic Piston Filling Capping Machine: This type of machine uses piston fillers to accurately dispense liquid solutions into bottles or vials. It offers high precision and is suitable for a wide range of viscosities.

2. Peristaltic Pump Filling Capping Machine: These machines utilize peristaltic pumps to precisely fill liquid solutions into bottles or vials. They are ideal for applications requiring high accuracy and are commonly used for pharmaceutical products.

3. Volumetric Filling Capping Machine: Volumetric filling machines use a predetermined volume to fill liquid solutions into bottles or vials. They are versatile and can handle various bottle or vial sizes.

4. Rotary Filling Capping Machine: Rotary machines are designed for high-speed production. They feature multiple filling and capping stations that work simultaneously, increasing efficiency and throughput.

5. Monoblock Filling Capping Machine: Monoblock machines combine the filling and capping processes into a single unit. They offer a compact design and are suitable for smaller production lines or limited space.

6. Semi-Automatic Filling Capping Machine: These machines require some manual intervention, such as manually placing bottles or vials or activating the filling and capping process. They are suitable for smaller-scale production or when automation is not required at every step.

7. Closed Restricted Access Barrier System (cRABS) Filling Capping Machine: cRABS machines provide a controlled and sterile environment for the filling and capping process. They feature a closed system with restricted access, minimizing the risk of contamination and ensuring product safety.

8. Isolator Filling Capping Machine: Isolator machines offer a fully enclosed and sterile environment for the filling and capping process. They provide a high level of operator and product protection, making them suitable for highly sensitive or hazardous products.

It's important to note that the availability of these types of machines may vary depending on the manufacturer and specific requirements. Manufacturers often offer customization options to tailor the machine to the specific needs of pharmaceutical solution filling and capping processes.

MACHINE VIDEO:

APPLICATION:

Medicated oil, balm oil, massage oil, beard oil, tincture, serum, CBD oil, hemp oil, cannabis oil, and cosmetic oil, hair oil, liquid drops, zinc supplement, eye drops, ear drops, saline nasal.

- 2024-11-14

- 2024-10-25

- 2024-10-21

- 2024-09-24

- 2024-09-12