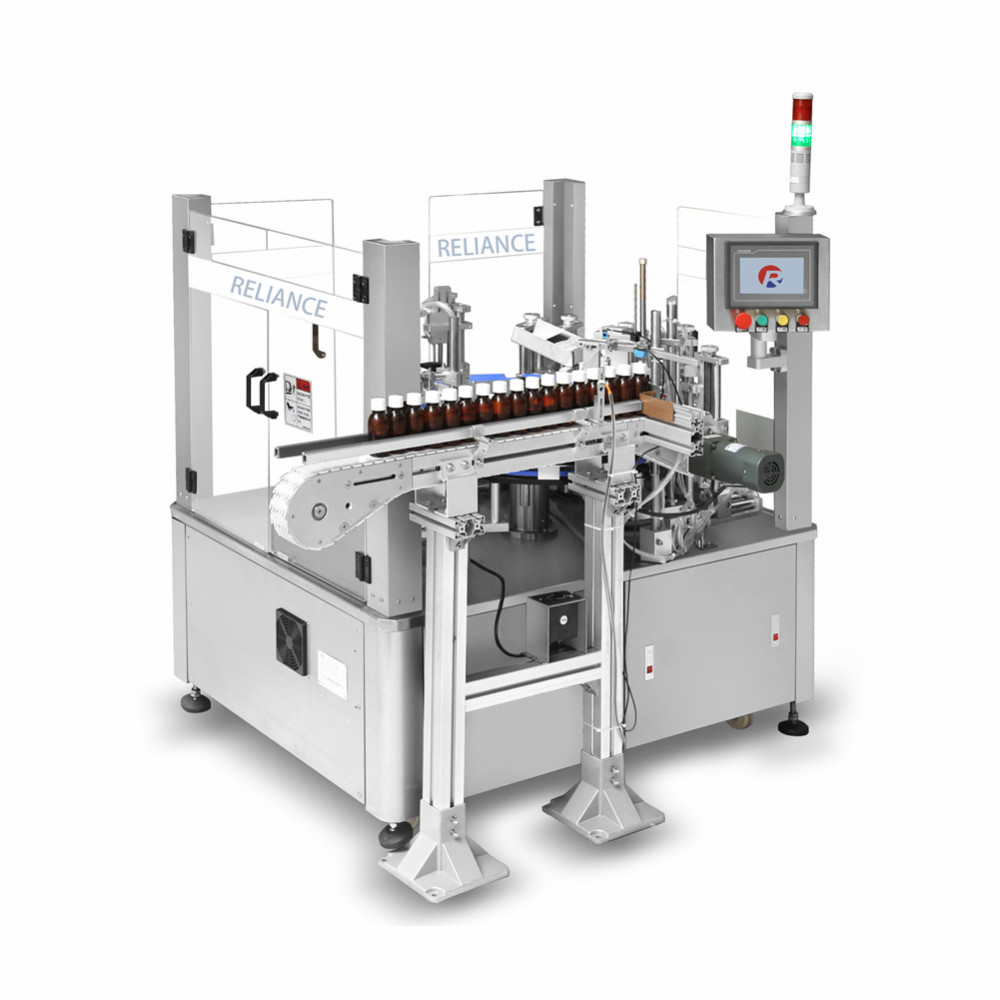

GMP Ceramic Pump 10ML Sterile Liquid Monoblock Filling Plugging Capping Machine

#CeramicPumpFillingMachine #10mlMonoblockFillingMachine #FillingPluggingCappingMachine #GMPFillingMachine #RelianceMachinery

DESCRIPTION:

RELIANCE Model RVF Automatic GMP Ceramic Pump 10ML Sterile Liquid Monoblock Filling Plugging Capping Machine is designed for automatic 1ml to 50ml aseptic liquid bottle filling, inner plugging, and capping onto small containers (eye/ear drop, saline drop, eyewash, oral solution, plastic or glass vial, e-liquid, nasal spray, cosmetics).

Automatic Monoblock 1ml 5ml, 10ml, 15ml, 30ml Sterile Eye drops/ ear drops/ nasal drops are used for a wide variety of medical applications, from simple eye moistening to local anesthesia. Compared to most liquid pharmaceutical products, the profit margins are often lower. This makes it important to be able to guarantee efficient and cost-effective processing for both pharmacy-only products and the over-the-counter (OTC) sector.

RELIANCE Monoblock-type liquid filling and capping machine for eye drops, nasal spray, and ear drops provides the highest level of flexibility. Whether small batches or large batches, whether for product development and clinical studies or commercial production, our solutions have a performance range of 30 to 120 units per minute (1800 - 7200 units per hour). These automatic lines can process containers made of glass as well as made of plastic.

1. Bottles are loaded onto a conveyor system.

2. The machine fills each bottle with the precise amount of liquid medication.

3. The filled bottles are then transported to the capping station where caps or seals are applied.

4. Once capped, the bottles are ready for labeling and packaging.

FEATURE:

1. Design by Compact combination set of bottle feeding, Nitrogen air filling, liquid filling, plugging & capping machines, providing labor savings & low space requirement.

2. Accurate volumetric filling designed by ceramic cylindrical pistons, filling tolerance is within ±1%.

3. All liquid contacts are made from corrosion-resistant stainless steel 316, meeting the standards of CGMP.

4. Labor-saving

5. Optional nitrogen filling device.

6. Compact combination set of bottle feeding, Nitrogen air filling, liquid filling, plugging & capping machine, providing labor savings & low space requirement.

7. Accurate volumetric filling designed by ceramic cylindrical pistons, filling tolerance is within ±1%.

8. Ceramic filling piston and cylinder: able to wear away freely, able to be contaminated freely, with free particles, and able to be cleaned easily.

9. The housing and surface are covered with stainless steel. All liquid contacts are made from corrosion-resistant stainless steel 316, meeting the standards of CGMP.

10. Labor-saving: The fillers have two container feeding systems. An automatic vibrating feeding system has been adopted in one, and an automatic turntable feeding system in the other. (option)

11. Optional nitrogen filling device.

12. The liquid filler has adopted two filling stages available for a gradual upward movement from the bottom of the bottle to prevent spills and the forming of foam.

13. Two inner plug feeding vibrators, ensure the inner plug is inserted into the bottle mouth smoothly.

14. The capping system includes cap vibrating feeding and capping with torque limiters that ensure caps are tightened.

15. Automatic stop device for no bottle, no plug, no cap, and low air pressure.

16. Equipped with a torque limiter under the star wheel, in case the machine stops due to

crash of the container on the star wheel which in turn then protects the Index device.

17. This machine is controlled by a PLC, ensuring that no bottles are fed, no liquid is filled, no liquid is filled, no plugs are inserted, no plugs are inserted no caps are capped.

SPECIFICATION:

|

Machine |

10ML Aseptic Eye Dropper Bottle Monoblock Filling Stoppering Capping Machine |

|

Model |

RVFE ( RELIANCE MACHINERY ) |

|

Application |

Eye drops, Ear drops, Nasal drops, Saline drops, Eye care, Ophthalmic, Aseptic |

|

Filling Range |

1ml-50ml |

|

Operating System |

Automatic |

|

Fill Accuracy |

+/-0.5 % |

|

Pump |

Piston pump, Peristaltic Pump, Volumetric Pump, Ceramic Pump |

|

Tank |

50L.- 100L |

|

Filler |

2- 4 Head- Filler with servo Drive |

|

Crimping Unit |

1- 2 heads |

|

Variable Speed Drive |

Delta Make |

|

Turret |

12 station- Indexing mechanism with motor drive |

|

Bottle Holder |

Cup type as per bottle diameter |

|

Conveyor |

Infeed-Outfeed with turn-table & 0.75kw Motor Drive |

|

Filling in |

Glass Bottles, tubes, vials, containers |

|

Construction |

316L Stainless Steel |

|

Contact Parts |

Stainless Steel 304 Grade/316 Grade (as per request) meet GMP and FDA |

|

Controller |

Electric Control Panel |

|

Drives |

Electric Motor / Servo Motors |

|

Additional Feature |

No-Bottle-No-Fill sensor, No–Stopper pick up and place on – No Caps Sensor |

|

Power Consumption |

1.5KW |

|

Air consumption |

6cfm – 7kg |

|

Power Supply |

220V Single Phase,110V Single Phase/50Hz(60Hz) |

|

Dimension |

2800mmL x1500mmW x 1750mmH |

|

Weight |

800kg - 1200 kg |

|

Output |

50 - 100 Bottles Per Minute |

OPTIONAL:

1. Liquid buffer/storage tanks.

2. Bottle buffering table

3. Safe door

4. Bottleneck holders

5. Rinser station before filling system station

6. Anti-drip filling nozzles for oils

7. Rejection station

8. Piston pump, Ceramic pump, and peristaltic pump as optional

APPLICATION:

Medicated oil, balm oil, massage oil, beard oil, tincture, serum, CBD oil, hemp oil, cannabis oil, cosmetic oil, hair oil, liquid drops, zinc supplement, ear oil, eye drops, ear drops, saline nasal, probiotic liquid drop.

MACHINE VIDEO:

- 2024-11-14

- 2024-10-25

- 2024-10-21

- 2024-09-24

- 2024-09-12