-

High Speed 4Oz Glass Dropper Bottle Filling Pipette Install and Capping Machine

High-speed 4Oz Glass Dropper Bottle Filling Pipette Install and Capping Machine, with Peristaltic Pump Liquid Filling Technology driven by a servo motor system, is suitable for Round, Oval, Flat, or square Bottles with a maximum speed of 150 bottles/min, used in CBD, Cannabis, and hemp oil products.

#DropperBottleFilling #HighSpeedFilling #PeristalticPumpFilling #ServoFillingMachine #RotaryTypeFiller #RelianceMachinery$ 0.00Buy Now

-

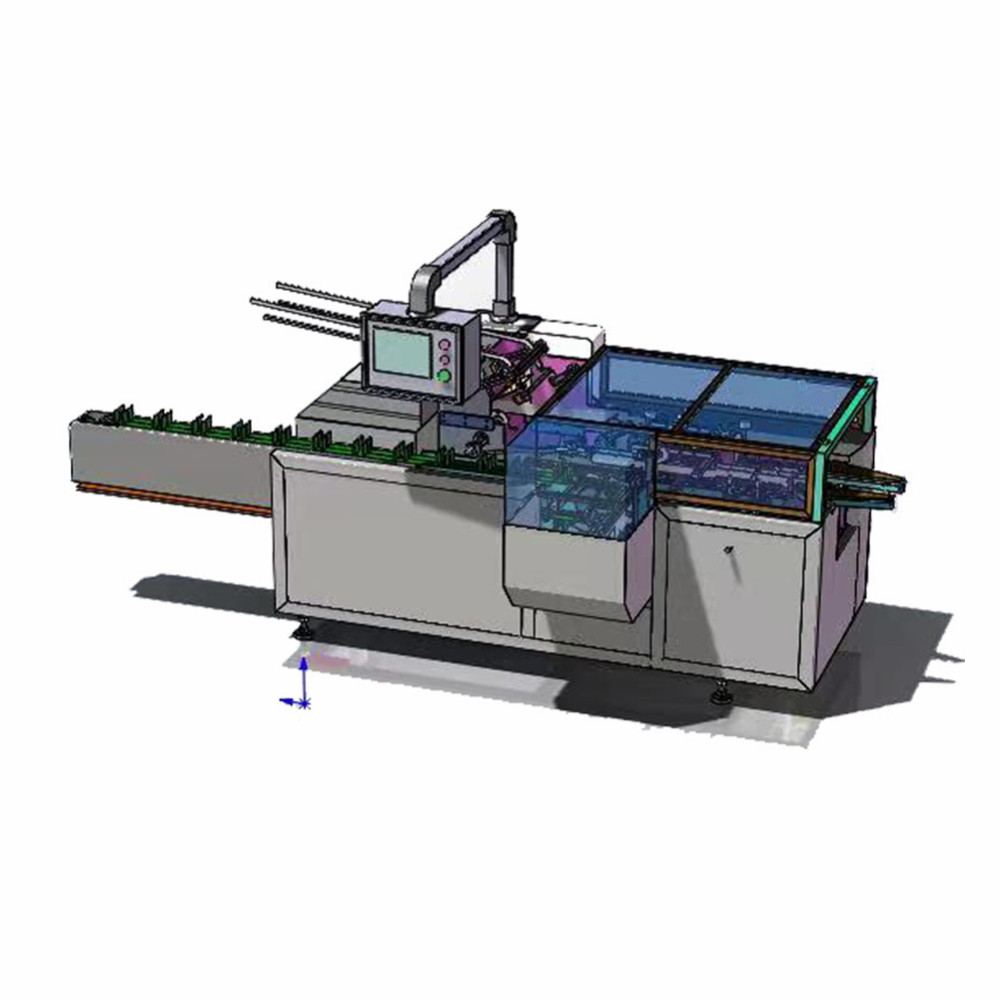

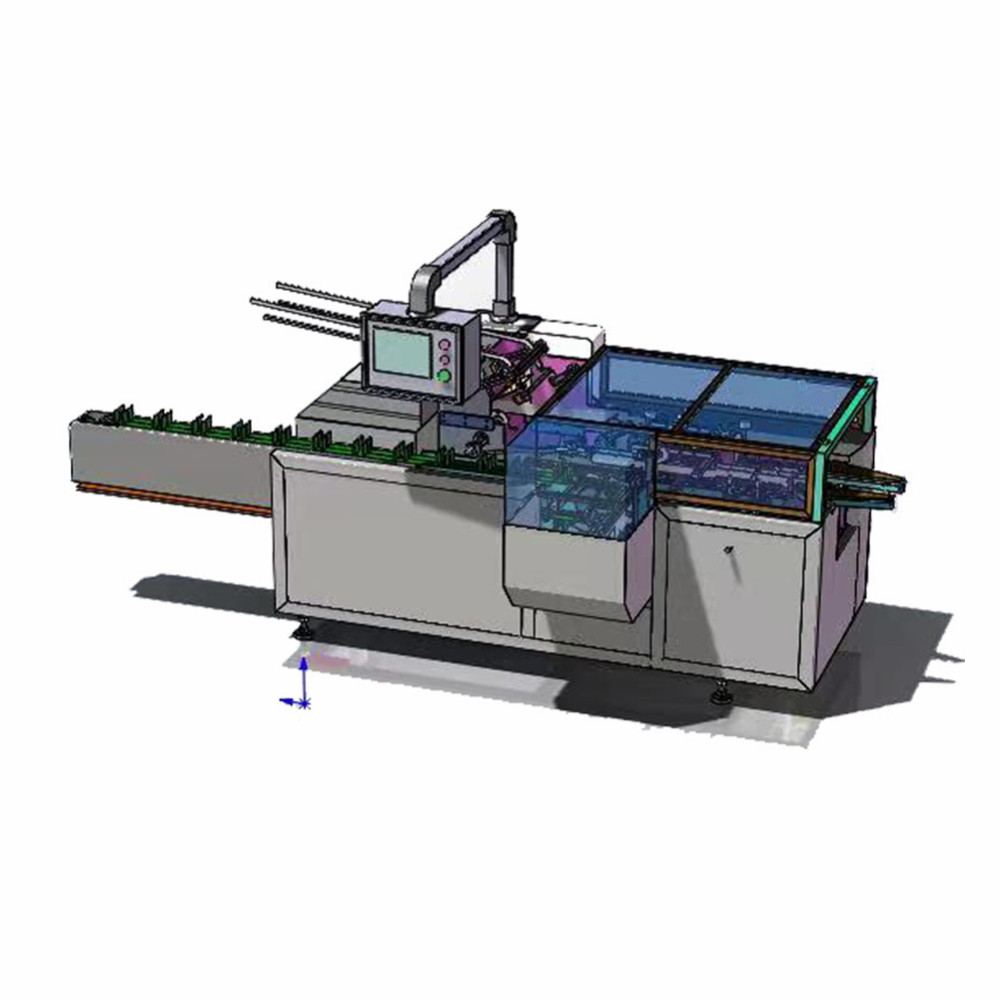

High Speed 10ML Roll On Essential Oil Glass Bottle Cartoner Machine

A horizontal High-Speed 10ML Roll On Essential Oil Glass Bottle Cartoner Machine is a device that automatically loads 1ml, 3ml, 5ml, 10ml, and 20ml tube glass roller on bottles and instructions into folding cartons and completes the action of closing the box.

#HighSpeedCartoner #HorizontalCartonerMachine #RollOnCartoner #RelianceMachinery$ 0.00Buy Now

-

Automatic Tincture Filling Capping Machine

Monoblock-type automatic Tincture Glass Dropper Bottle Filling and Capping Machine, a state-of-the-art solution from Reliance Machinery, tailored for the efficient and precise packaging of CBD Oil products.

R-VF$ 0.00Buy Now