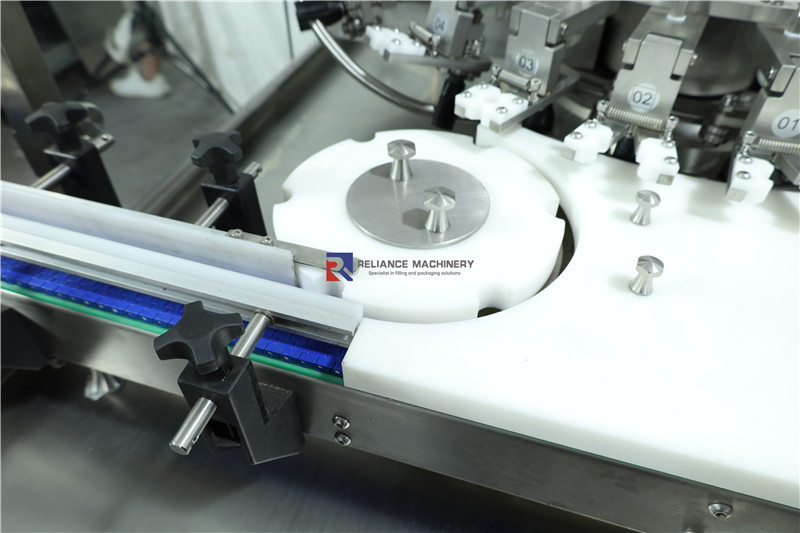

High Speed Rotary Type Bottle Capping Machine

Function: The Rotary-type high-speed glass and plastic bottle air washing machines represents a significant advancement in beverage packaging technology. These machines are designed to efficiently clean bottles before filling, ensuring product quality and hygiene standards are met. With their rotary design and high-speed capabilities, they offer increased throughput and productivity compared to traditional washing methods, making them indispensable in modern production facilities.

Features: In the pharmaceutical and supplement industries, the rotary-type high-speed glass and plastic bottle air washing machines play a crucial role in ensuring the cleanliness and safety of packaging materials. These machines are specifically designed to meet the stringent requirements of pharmaceutical and supplement production, where hygiene and product integrity are paramount.

Key features of these machines in pharmaceutical and supplement applications include:

1. Compliance with Regulations: Rotary-type air washing machines are built to adhere to strict regulatory standards such as Good Manufacturing Practices (GMP) and FDA regulations, ensuring compliance with industry guidelines.

2. Versatility: These machines are versatile and can handle a wide range of bottle sizes and shapes commonly used in pharmaceutical and supplement packaging. They are equipped with adjustable settings to accommodate various bottle types, allowing for flexibility in production.

3. High-speed Operation: High-speed capabilities enable rapid cleaning of bottles, increasing production efficiency and throughput. This is essential in pharmaceutical and supplement manufacturing, where large quantities of bottles need to be processed quickly.

4. Precision Cleaning: Rotary-type air washing machines utilize advanced cleaning mechanisms to remove contaminants such as dust, debris, and residues from both the interior and exterior of bottles with precision. This ensures that bottles are thoroughly cleaned and free from any potential contaminants before filling.

5. Air Washing Technology: These machines utilize air washing technology, which involves blowing high-pressure air into the bottles to dislodge and remove particles and contaminants. This non-contact cleaning method minimizes the risk of cross-contamination and ensures a sterile environment for pharmaceutical and supplement products.

6. Integrated Drying System: Many rotary-type air washing machines feature integrated drying systems that remove excess moisture from the bottles after washing. This helps prevent moisture-related issues such as bacterial growth and product degradation, ensuring product stability and shelf life.

7. Quality Assurance: By effectively cleaning and sanitizing bottles, these machines contribute to maintaining the quality and integrity of pharmaceutical and supplement products, reducing the risk of product recalls and ensuring consumer safety.

The rotary-type high-speed glass and plastic bottle air washing machines has revolutionized the packaging process in the pharmaceutical and supplement industries, enhancing efficiency, compliance, and product quality.

Advantages: The advantages of rotary-type high-speed glass and plastic bottle air washing machines in pharmaceutical and supplement applications include:

1. Efficiency: These machines offer high-speed operation, allowing for rapid cleaning and processing of bottles, thus increasing overall production efficiency.

2. Precision Cleaning: Advanced cleaning mechanisms ensure thorough removal of contaminants from both the interior and exterior of bottles, maintaining high hygiene standards required for pharmaceutical and supplement packaging.

3. Versatility: Rotary-type air washing machines are versatile and can accommodate a wide range of bottle sizes and shapes, providing flexibility in production setups.

4. Compliance: Designed to meet strict regulatory standards such as Good Manufacturing Practices (GMP) and FDA regulations, these machines ensure compliance with industry guidelines and quality standards.

5. Reduced Risk of Contamination: Non-contact air washing technology minimizes the risk of cross-contamination, ensuring a sterile environment for pharmaceutical and supplement products.

6. Integrated Drying System: Many machines feature integrated drying systems that remove excess moisture from bottles after washing, reducing the risk of bacterial growth and product degradation.

7. Quality Assurance: By effectively cleaning and sanitizing bottles, these machines contribute to maintaining the quality and integrity of pharmaceutical and supplement products, reducing the likelihood of product recalls and ensuring consumer safety.

The advantages of rotary-type high-speed glass and plastic bottle air washing machines lie in their ability to enhance production efficiency, ensure product quality, and meet regulatory requirements in pharmaceutical and supplement manufacturing processes.

Applications:

- Pharmaceutical Industry: Capsules, tablets, liquid medicines.

- Food and Beverage Industry: Bottled water, juices, sauces, condiments.

- Cosmetic Industry: Lotions, shampoos, creams, perfumes.

MACHINE VIDEO:

-

High Speed 1ML To 10ML Roll On Bottle Filling Capping Machine for Herb Perfume Oil

Automatic High Speed 1ML To 10ML Roll On Bottle Filling Capping Machine, designed by Reliance Machinery, monoblock type, application for medicated oil, massage oil, perfume, herb oil, hair oil, essential oil,

#reliancemachinery #highspeedrollonfillingmachine #rollonfillingcappingmachine #10mlrolonfillingmachine #monoblockfillingcappingmachine #medicatedoil #perfumefilling -

Tips on the use and maintenance of peristaltic pumps in liquid filling machine system

Peristaltic pumps are known for their low maintenance costs, but where does this really translate? Only companies that have personally experienced peristaltic pumps can truly understand how much cost it saves users.

#useperistalticpump #peristalticpumpmaintenance #liquidfillingsystem #reliancemachinery #peritalticpumparticle -

The feature of pharmaceutical products cartoning packing machine

The feature of pharmaceutical products cartoning packing machine is that it has the advantages of small size, lightweight, wide application range, high production efficiency, and can be used for multiple purposes in one machine.

#CartoningMachineFeature #FeatureofcartoningMachine #pharmaceuticalcartoningmachine #RelianceMachinery -

Documentation for Validation in pharmaceutical filling and capping machine

Documentation for Validation in pharmaceutical filling and capping machines, The list goes on with IQ (Installation qualification), OQ (Operational Qualification), PQ (Performance Qualification), FDS (Functional design specifics), HDS (Hardware design specifics), and Risk analysis.

#DocumentationFillingMachine #reliancemachinery #pharmaceuticalvalidation #fillingcappingmachine #FDA -

Automatic horizontal high speed Cartoning machines for pharmaceutical products

Automatic horizontal high-speed Cartoning machines for pharmaceutical and cosmetic, food industry, applications for sachets/stick packs with loading conveyor.

#reliancemachinery #highspeedcartonermachine #pharmaceuticalcartonermachine #bagcartonermachine #boxpackingmachine #horizontalcartonermachine #pharmaceuticalpackingmachine -

Principle and Useage of zirconia ceramic filling pump in pharmaceutical liquid filling machine

The zirconia ceramic filling pump is a high-precision liquid filling and metering pump. The metering parts of this product are made of new precision ceramic materials that are wear-resistant, corrosion-resistant, and high-temperature resistant and are processed with ultra-precision.

#PrincipleFillingPump #CeramicFillingPump #ZirconiaFillingPump #FillingSystem #RelianceMachinery