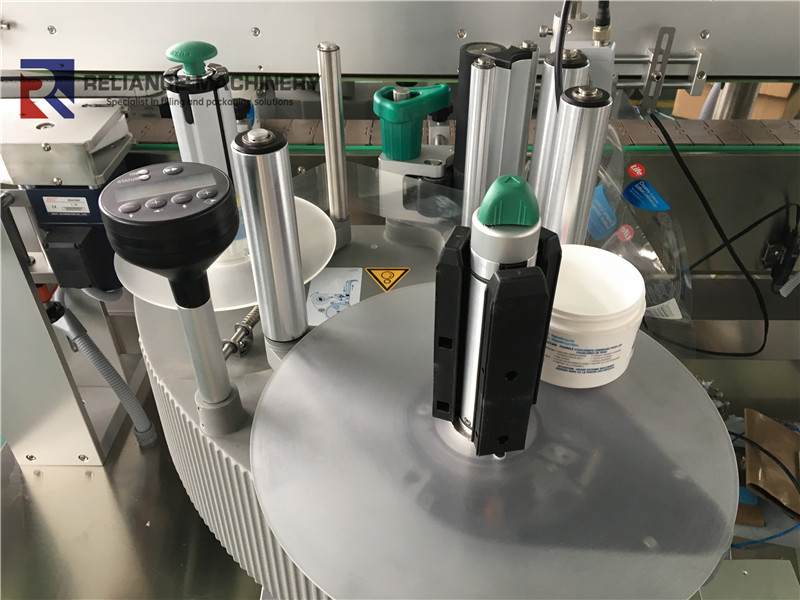

Front and Back Sticker Labeler Machine

DESCRIPTION:

The Front & Back Sticker Labeler Machine is built to automatically apply pressure sensitive labels onto the front and/or back of the square, flat-sided, oval, and some round containers. The RVFD can be ordered with one or two labeling heads and has an optional assembly for applying a label to 3, 4, or 5 panels of a square or rectangular container. The RVFD front band back labeling equipment is an ideal machine for contract packagers and manufacturers serving the food, nutraceutical, pharmaceutical, gas, oil, cosmetics and personal care markets.

COMPOSITION AND STRUCTURE:

1. Bracket: supports the entire equipment and work surface.

2. Adjustment device: The labeling position, height, and angle can be adjusted to meet different labeling needs.

3. Slitting device: After slitting the label, it enters the labeling setting area.

4. Sensor: It can sense the surface of the object, control the automatic labeling, automatically determine whether the label is adhered in place, and ensure the flatness and accuracy of label pasting.

5. Control system: controls the operation, labeling speed, and accuracy of the entire equipment.

WORKING PRINCIPLE:

(1) During label delivery, the label is taken out of the label library by the robot and passes through the slitting device, where it is cut into independent labels and prepared for placement.

(2) The labeled object enters the label loading area. After the sensor detects that the object is in place, it automatically detects the position and size of the object.

(3) The control system will automatically fine-tune the adjustment device to make the label fit the surface of the object being attached. After the label is attached to the item, the sensor detects the fit and determines whether the label is in place.

(4) Once the bonding is completed, the sensor will send an execution command to the controller, and the label feeding and loading work will stop. After the labeling work is completed, the manipulator will lift up and wait for the next cycle to send labels again.

(5) During the entire working process, the control system will continuously recalculate the position of the item and the adhesion of the label so that the label fits the item as closely as possible.

FEATURE:

1. The height of the angel of the labeling machine can be adjustable

2. The conveyor and labeling speed can be adjustable

3. PLC control, easy to operate, LED screen, easy to read the labeling times

4. Easy to change labels in different sizes and dimensions

5. Small compact design suit for small capacity products and lab use

6. All built with 304 Stainless steel

7. Provided with 10-30 sets of memory to save parameters from different production lines and is convenient to adjust various productions.

8. Active detection system gives the alarm and the machine stops working when out of carbon fiber tape

9. Smart detection system for missing labeling to guarantee labeling quality

SPECIFICATION:

1. Driving device: all servo motor drive

2. Labels apply speed: ≤35 meters/minute

3. Bottle specifications: φ10-φ50mm

4. Label specifications: Label reel core inner diameter: φ76mm

Maximum outer diameter of label roll: φ350mm

Label length: (16mm - 200mm) mm

Label width: 15-200mm

4. Power supply: 750W/ 110V/ 220V/50Hz

5. Normal surface temperature of motor: 70℃

6. Labeling accuracy: ±0.5mm

7. Overall dimensions: (L)1800 mm x (W)1000mm x (H) 1350mm

8. Machine weight: 650Kg

OPTIONAL:

1. Set of pneumatic wrap station (for labeling 3/4 to 1 circle around the bottle)

2. Transparent label sensor

3. Date/batch number coder/ hot stamping printer / Jet printer or thermal transfer machine

4. Adjustable labeling head angle adjustment for micro conical bottles

5. Customized rolling assembly and bottle dividing screw assembly

6. Automatic feeding & collection turntable (driven by a motor)

7. Conveyor belt lengthening at the entrance and exit ends

8. There is no printing detection, and there is no printing detection and shutdown.

MACHINE VIDEO:

- 2024-10-25

- 2024-10-21

- 2024-09-24

- 2024-09-12

- 2024-09-12