HOW TO CHOOSE A FILLING MACHINE?

Whether you are creating a new filling and packing plant or automating an existing line, considering an individual machine, or investing in a complete line, purchasing modern equipment can be an uphill task. A point to remember is that the liquid filling machine is the one machine in direct contact with your liquid product. So besides operational efficiency, it needs to handle your product with care, without compromising on product quality and hygiene.

There are many aspects and criteria to be considered when selecting the best liquid filling machine for your enterprise. Let’s discuss 5 of the most basic ones:

1. Filling machine output requirements: When selecting a filling machine, select the corresponding model of the filling machine according to the product output requirements. For example, the hourly output of a single-station filling machine is 1800 bottles/hour, the hourly output of a double-station filling machine is 3600 bottles/hour, and the hourly output of a high-speed rotary filling machine is 7200 bottles/hour. Products can also be customized according to needs.

2. Function of the filling machine: It is very important to choose the appropriate filling machine according to the functional requirements. For example, many pharmaceutical manufacturers need to clean the filling machine after filling and producing the products. You can choose Convenient disassembly function. For example, during the filling production of spray filling machines, many pharmaceutical manufacturers need to make the filling machine explosion-proof if the alcohol content reaches 75% and require an independent electrical cabinet. You can choose an explosion-proof filling machine. For another example, if some products require inkjet printing or coding, you can add laser inkjet coding or laser coding device. Of course, you can also choose inkjet coding or coding.

3. Filling machine usage area: Choose the filling machine model based on the usage area where the filling machine equipment can be placed in the company's production workshop. This should also be combined with the product's production capacity to select the model. For example, if the filling machine area reserved in your production workshop is large enough and the production capacity is high, you can choose a large filling machine equipment. If the filling machine area reserved is large enough, the production capacity is not high or the reserved area is relatively small. Small, at this time you can choose a disc filling machine, a semi-automatic filling machine, or a small desktop filling machine.

4. Subsequent reuse capability of the filling machine: Depending on the size of the enterprise's project, the model of the filling machine can be selected based on the reuse capability of the filling machine. This should also be combined with the project cycle of the product to select the reuse capability.

For example, the long-term project can achieve the service life of the filling machine of 10-20 years. If the output is increased or the production capacity is increased in the middle, the performance of the filling machine can be improved by modifying it. If the project is small, factors such as modifying the performance of the filling machine after use should be considered. The above is the introduction of relevant information on "Basic Factors for Selecting Filling Machines". I believe you already have a certain understanding of the selection of fully automatic filling machine models. The selection of the filling machine model is particularly important. You can tell the filling machine manufacturer the packaging requirements for all aspects of the product and tailor-make the filling machine for your own product.

PACKING PRODUCTS

-

Automatic Glass or Plastic Bottle Bottom Sticker Labeling Machine

The Automatic Glass or Plastic Bottle Bottom Sticker Labeling Machine is specifically designed for bottles, containers, vials, bags, boxes, and sticker labels on the bottom side, application on pharmaceutical and cosmetics.

#LabelingMachine #BottomLabeling #BottleBottleLabeling #AutomaticBottomLabeling #RelianceMachinery2024-04-15 -

Monoblock Automatic Aseptic Peristaltic Pump Glass Vials Filling Stoppering Machine

Monoblock Automatic Aseptic Peristaltic Pump Glass Vials Filling Stoppering Machine is a specialized industrial equipment designed for efficiently filling bottles and vials in bio and pharmaceutical industry.

#MonoblockFilling #AsepticFilling #PeristalticPumpFilling #VialsFillingStoppering2024-04-10 -

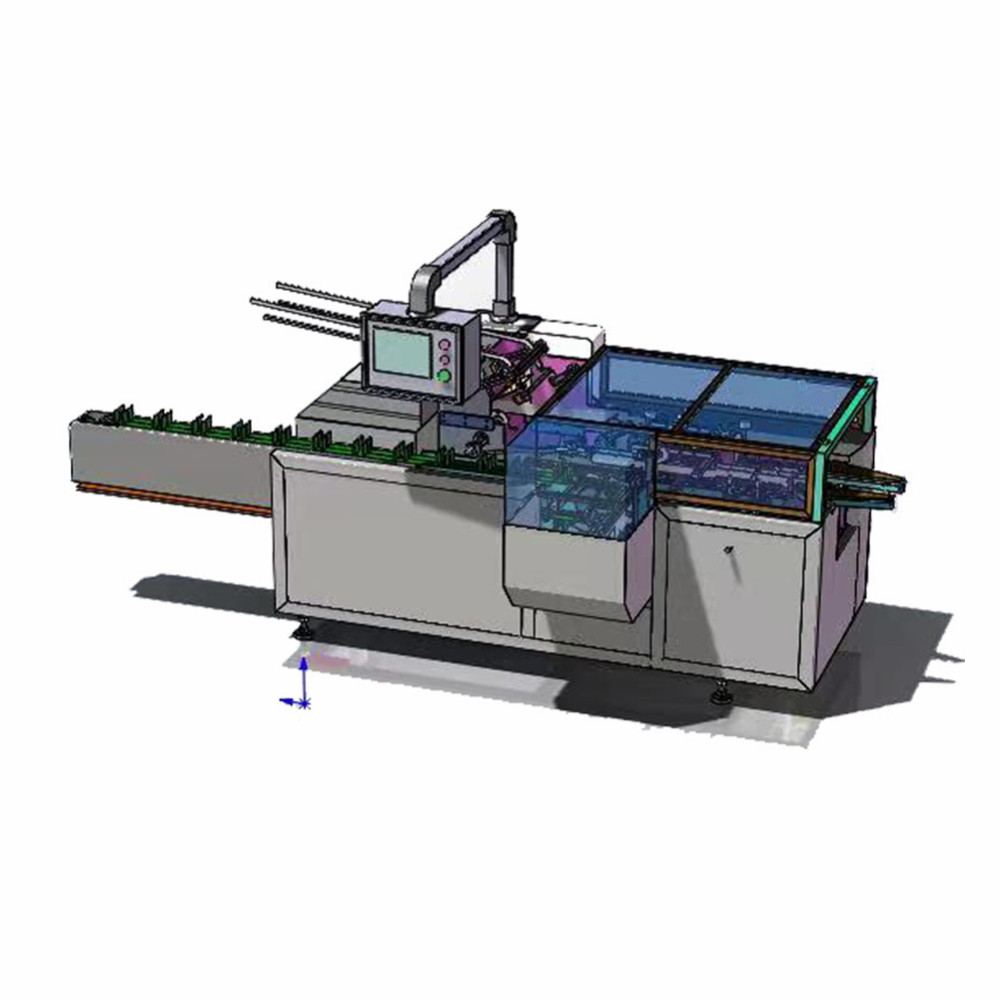

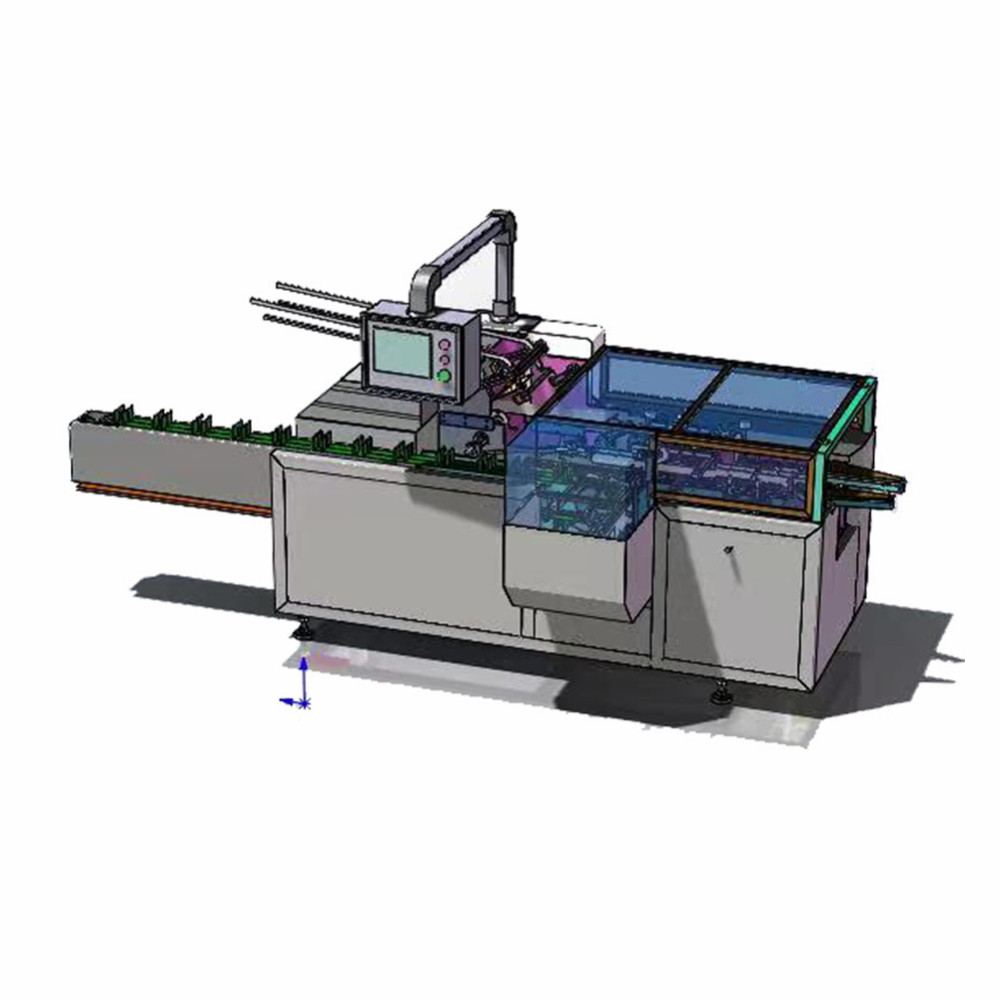

High Speed 10ML Roll On Essential Oil Glass Bottle Cartoner Machine

A horizontal High-Speed 10ML Roll On Essential Oil Glass Bottle Cartoner Machine is a device that automatically loads 1ml, 3ml, 5ml, 10ml, and 20ml tube glass roller on bottles and instructions into folding cartons and completes the action of closing the box.

#HighSpeedCartoner #HorizontalCartonerMachine #RollOnCartoner #RelianceMachinery2024-04-09 -

Linear Spindle Type Bottle Capper Machine

Series bottle Spindle capping machine covers single-head or double-head chuck, the indexed monoblock container capping machines provide nearly all of the perks of fully automated, customized cappers, without the hit to your company’s budget.

Model: RXGS2024-03-11 -

Bottle Liquid Filling Capping And Labeling Line

Complete line Modep R-VF Bottle Liquid Filling Capping And Model R-LB Labeling Line Packing system is widely used in the pharmaceutical, cosmetic, food, tincture essential, and supplement industries, etc. It is suitable for factory automation integrating the processes of liquids/oil/gel/serum filling, capping, and labeling into the smooth-flow production line. This model uses a high-level interfaced control system for fast speed and high-precision operation.

RVF+RLB2023-12-20 -

Horizontal Shrink Sleeve Labels Apply Machine

RELIANCE Model R-SLB/W horizontal high-speed sleeve shrink labeling machine with high tech film cutting system for slim bottles, small boxes such as lipstick, mascara, lipgloss, tube bottles, roll-on bottles, widely used in pharmaceuticals, cosmetics, and essential oil, medicated oil industry, etc. It has a compact design that includes film wrapping, cutting, and shrinking in one machine. Speed up to 80-100pcs/min.

Model: RSLBW2023-12-19 -

Bottle Unscrambler Machine

This automatic bottle unscrambler machine consists of a bottle storage mechanism, a bottle unscrambler turntable, and a bottle erecting mechanism. It is suitable for unscrambling plastic round bottles and flat bottles. Pour the messy bottles into the bottle unscrambler, and use the adjustable speed bottle unscrambler to unscramble the bottles. Enter the filling conveyor line upright and orderly

Model: RLP2023-12-07 -

Air Rinser Machine

RELIANCE RXPA Air Rinser can use compressed air and other air sources to rinse containers before filling or packing. Air Rinsing machines use nozzles to blow a stream of air into each container to loosen dust and debris.

Model: RXP/A2023-12-05