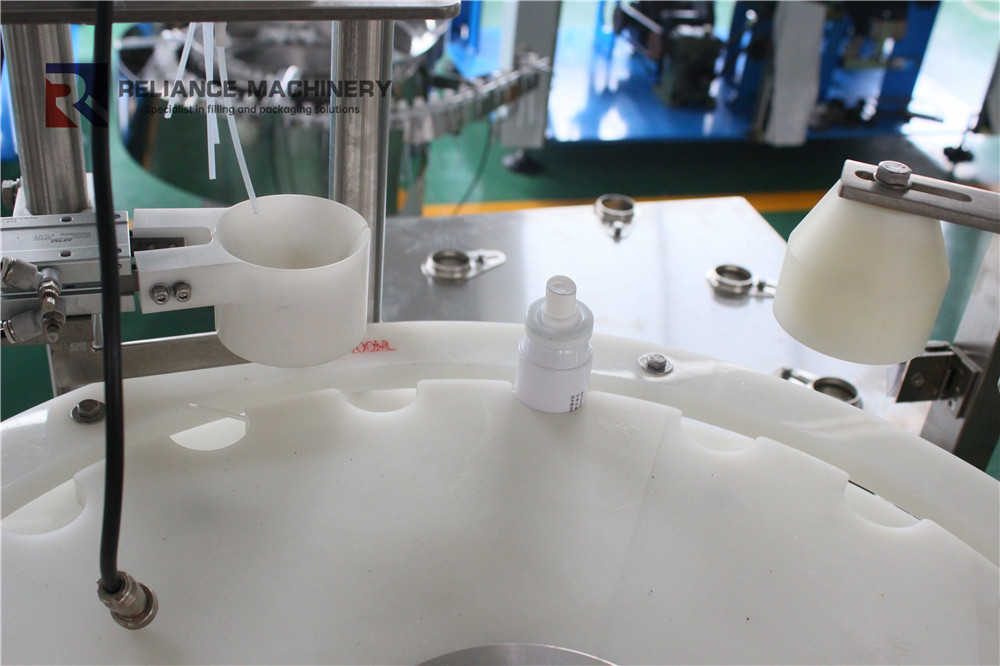

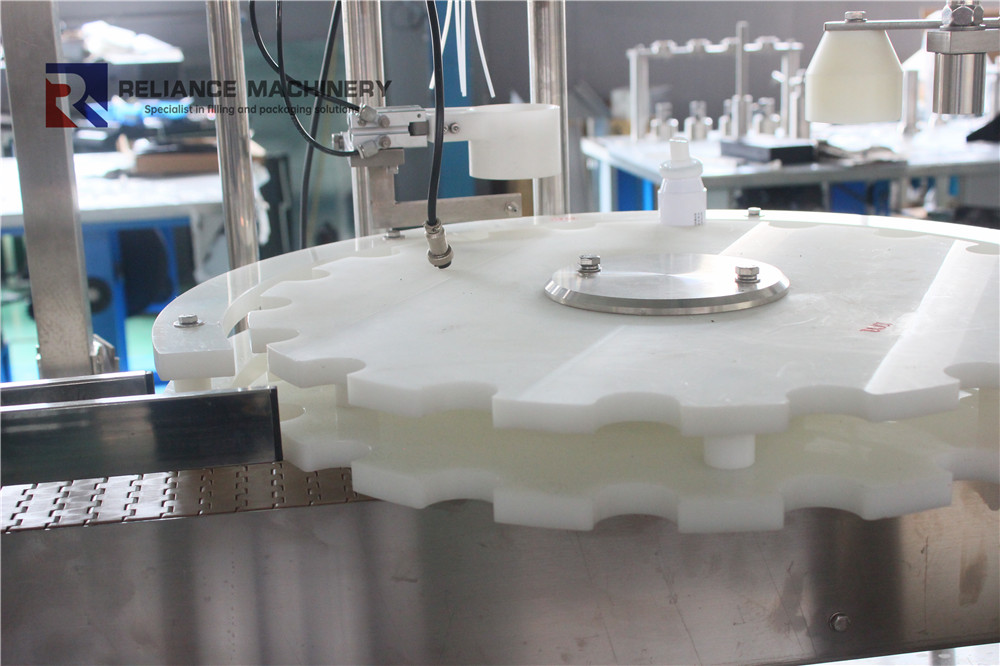

Manual Type Bottle Liquid Filler Capper Machine

R-MVF

DESCRIPTION:

The Manual Type Bottle Liquid Filler Capper Machine is a piece of equipment designed for small to medium-scale production lines, primarily used in industries such as pharmaceuticals, cosmetics, food and beverages, and chemicals. This machine combines the functions of filling and capping bottles with liquid products in a manual or semi-automatic manner, making it a versatile and cost-effective solution for businesses looking to automate their packaging processes without a significant investment in fully automated machinery.

FEATURE:

- Manual Operation: The machine requires an operator to manually place bottles under the filler and then move them to the capping area. This manual intervention allows for greater control over the filling and capping process, making it ideal for small batches or products that require special handling.

- Adjustable Volume: The filler part of the machine typically allows for adjustments in the volume of liquid dispensed, enabling it to accommodate bottles of different sizes and fill levels according to the product specifications.

- Versatile Capping: The capper can usually be adjusted to fit various bottle neck sizes and cap types, including screw caps, press-on caps, and more. This flexibility ensures that the machine can be used for a wide range of products without the need for extensive modifications.

- Compact Design: Given its manual or semi-automatic nature, the machine often has a compact design, making it suitable for operations with limited space. It can easily be integrated into existing production lines or used as a standalone unit.

- Ease of Maintenance: With fewer mechanical and electronic components than fully automated machines, the Manual Type Bottle Liquid Filler Capper Machine is generally easier and less costly to maintain.

SPECIFICATION:

1. Working mode: Pneumatic

2. Filling head: single head

3. Filling volume: 100ml-1000ml

4. Filling speed: 5-20 bottles/min

5. Filling accuracy: ≤±1%

6. Power supply: 110V 60HZ

7. Power: 10W

8. Speed: Approximate 2-50 r/min

9. Accuracy: ≤±1%

10. Rated air pressure: 0.4-0.6MPa

11. Applicable pressure: 0.4-0.6MPa

OPTIONAL:

1. Customized hopper for the material storage

2. Servo drive for the filling pump

3. Conveyor for the semi-automatic filler machine

MACHINE VIDEO:

APPLICATION:

Medicated oil, balm oil, massage oil, beard oil, tincture, serum, CBD oil, hemp oil, cannabis oil, and cosmetic oil, hair oil, liquid drops, zinc supplement.

- 2024-05-15

- 2024-05-12

- 2024-05-12

- 2024-05-11

- 2024-05-11