Top Bottom Sticker Labeler Machine

DESCRIPTION:

Top and bottom two sides labeler machine is specifically designed for special containers and is used for the products which needs twice labeling, such as bottles, vials, jars, cartoners, carton box. The labeling head is set up on the top and bottom of the labeler individually to achieve labeling two labels simultaneously. The production efficiency can reach up to 30-60 bottles/min. The top and bottom double sides labeler machine is suitable for various industries. When it needs to label top and bottom labels at the same time, you just need to place the whole label on the collecting plate of the top and bottom respectively. After the label is sucked by the labeling head, it can be accurately stuck on the fixed position of the object by the sensors, no matter it’s for flat, concave, or convex products, they all can be easily fitted. Products like, Salad Box, Yogurt Box, Cookie Box, Cardboard, Bottle Cap, Flat Bottle, Lipstick Bottom, and Mascara, etc. all can be labeled precisely and smoothly to meet your labeling requirements.

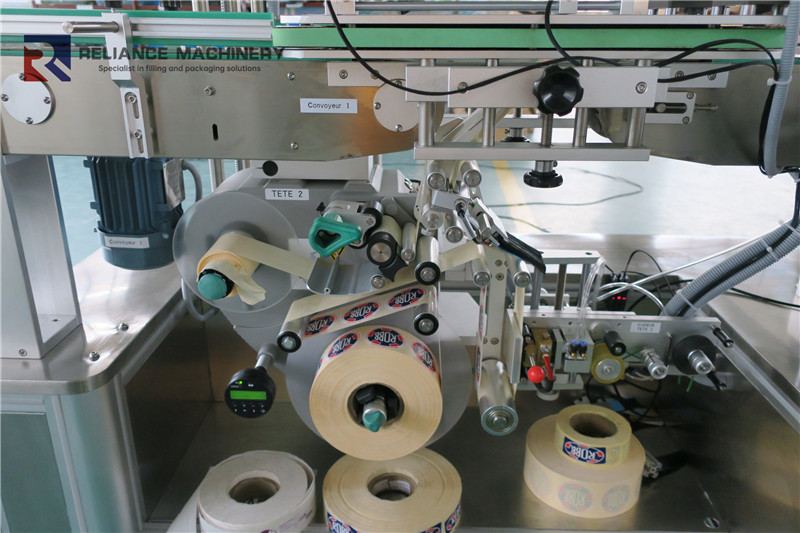

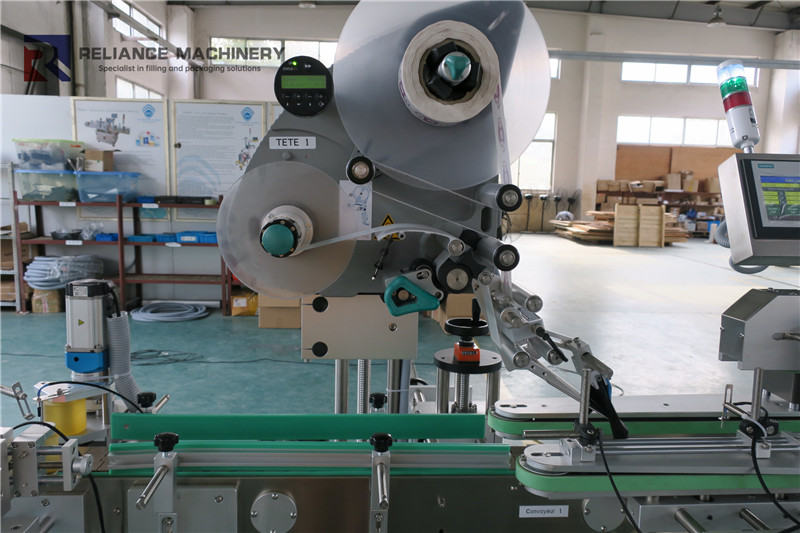

COMPOSITION AND STRUCTURE:

1. Bracket: supports the entire equipment and work surface.

2. Adjustment device: The labeling position, height, and angle can be adjusted to meet different labeling needs.

3. Slitting device: After slitting the label, it enters the labeling setting area.

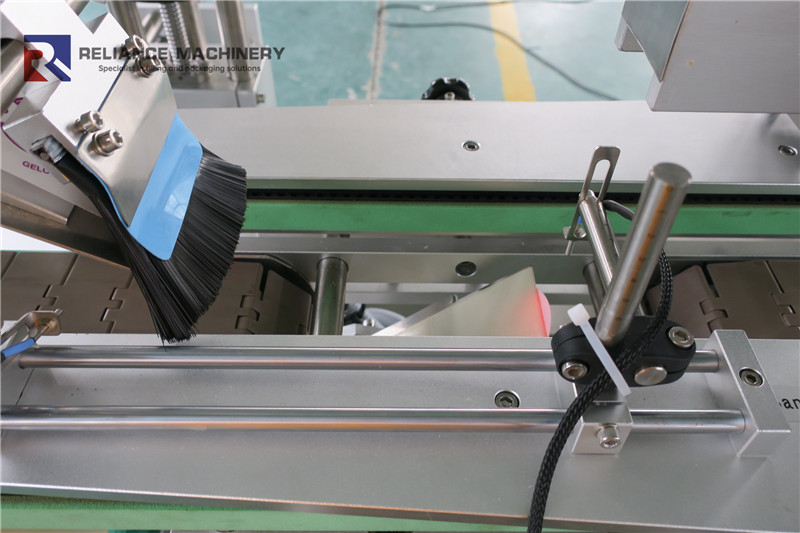

4. Sensor: It can sense the surface of the object, control the automatic labeling, automatically determine whether the label is adhered in place, and ensure the flatness and accuracy of label pasting.

5. Control system: controls the operation, labeling speed, and accuracy of the entire equipment.

WORKING PRINCIPLE:

(1) During label delivery, the label is taken out of the label library by the robot and passes through the slitting device, where it is cut into independent labels and prepared for placement.

(2) The labeled object enters the label loading area. After the sensor detects that the object is in place, it automatically detects the position and size of the object.

(3) The control system will automatically fine-tune the adjustment device to make the label fit the surface of the object being attached. After the label is attached to the item, the sensor detects the fit and determines whether the label is in place.

(4) Once the bonding is completed, the sensor will send an execution command to the controller, and the label feeding and loading work will stop. After the labeling work is completed, the manipulator will lift up and wait for the next cycle to send labels again.

(5) During the entire working process, the control system will continuously recalculate the position of the item and the adhesion of the label so that the label fits the item as closely as possible.

FEATURE:

1. The height of the angel of the labeling machine can be adjustable

2. The conveyor and labeling speed can be adjustable

3. PLC control, easy to operate, LED screen, easy to read the labeling times

4. Easy to change labels in different sizes and dimensions

5. Small compact design suit for small capacity products and lab use

6. All built with 304 Stainless steel

7. Provided with 10-30 sets of memory to save parameters from different production lines and is convenient to adjust various productions.

8. Active detection system gives the alarm and the machine stops working when out of carbon fiber tape

9. Smart detection system for missing labeling to guarantee labeling quality

SPECIFICATION:

1. Speed: 30-50pcs/min

2. Labeling width: 10-100mm

3. Labeling length: 20-300mm

4. Accuracy: ±1mm

5. The labeling head is driven by a stepper motor or servo motor

6. Label reel: (ID) 76mm (OD)300mm

7. Power requirement: Single phase, 110 or 220 VAC, 50/60Hz

8. Machine dimension: (L)2001 mm (W)803mm (H)1700mm

9. Overall dimensions: (L)1800 mm x (W)1000mm x (H) 1350mm

10. Machine weight: 650Kg

OPTIONAL:

1. Hot Stamp (Lot/Date Coding)

2. Missing Hot Stamp Imprint Check

3. Integrated Thermal Printer (Lot/Date, Bar Code and Graphics)

4. Dataflex or Similar Lot/Date Code Printer

5. Clear, Metalic or Color Label Sensor

6. End to end Transfer Plates

7. Infeed and outfeed Conveyor Extensions

8. Separator Wheel for Controlled Spacing

9. Automatic feeding & collection turntable (driven by a motor)

10. Conveyor belt lengthening at the entrance and exit ends

11. There is no printing detection, and there is no printing detection and shutdown.

MACHINE VIDEO:

- 2024-05-15

- 2024-05-12

- 2024-05-12

- 2024-05-11

- 2024-05-11