Tips on the use and maintenance of peristaltic pumps in liquid filling machine system

Tips on the use and maintenance of peristaltic pumps!

Peristaltic pumps are known for their low maintenance costs, but where does this really translate? Only companies that have personally experienced peristaltic pumps can truly understand how much cost it saves users.

Compared with other pumps, the maintenance of peristaltic pumps is simpler and more convenient. Traditional pumps usually require five or six hours to maintain and repair the transmission medium, but peristaltic pumps only need to replace the pump tube.

During the maintenance process, there is no need to move, transfer or reinstall the equipment, which greatly improves work efficiency.

Moreover, the peristaltic pump does not need to be cleaned, because only the pump tube, not the pump itself, is

in contact with the pump during its liquid transfer process. The maintenance cycle of the pump body is also very long. If it is in good condition, it can be maintained once every six months.

It can be said that as long as the daily maintenance of the peristaltic pump is good, you can use it with twice the result with half the effort!

Seven tips to improve work efficiency:

1. Peristaltic pump maintenance: When the peristaltic pump stops working, remember to loosen the pump head pressure tube module. Doing this will maximize hose life and maintain its flexibility and performance.

2. Reduce the rotation speed and increase the diameter of the pump tube: When selecting a peristaltic pump, you can reduce the rotation speed and increase the diameter of the hose to reduce hose wear and extend service life.

3. Choose the right connector: It is very important to choose the right hose connector to reduce resistance and flow loss. Make sure the diameter of the hose connector is not smaller than the diameter of the pump head, and keep the hose inlet as short as possible.

4. Select the appropriate flow rate: When selecting a peristaltic pump, the theoretical flow rate should be greater than the actual flow rate to make up for the flow loss that may occur during the working process.

5. Clean the pump casing and pump tubes regularly: Regularly cleaning the casing and pump tubes of the peristaltic pump can prevent debris from entering the pump and reduce wear and damage.

6. Regularly check the wear of the pump tube: Regularly check the wear of the pump tube and replace seriously worn pump tubes in time to avoid leakage and reduce transmission efficiency.

7. Choose the appropriate pump tube material: In order to minimize wear, it is recommended to use special peristaltic pump tubes. And according to the characteristics of the transported liquid, appropriate pump tube materials need to be selected to ensure that the pump tube can withstand the corrosion and wear of the liquid.

The above tips can help you make better use of peristaltic pumps, improve work efficiency, extend the service life of equipment, and reduce maintenance costs.

Relative Products of peristaltic pump filling and capping machine:

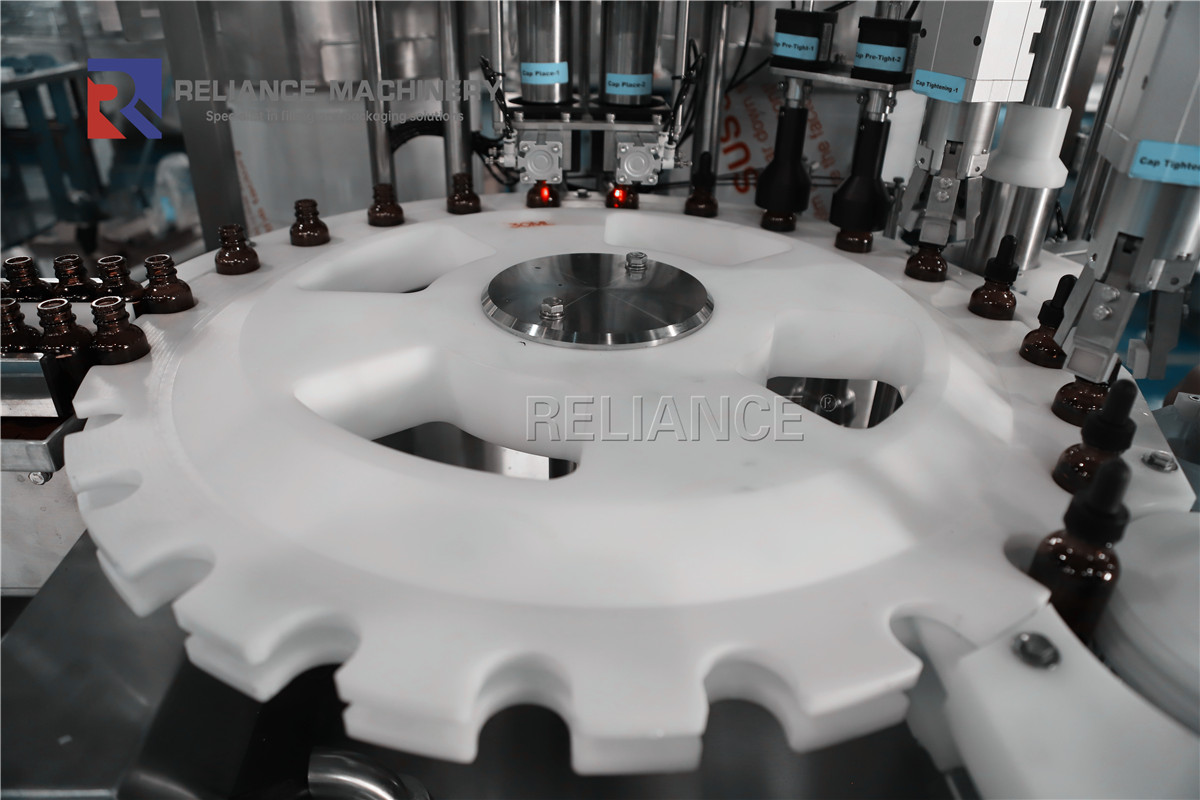

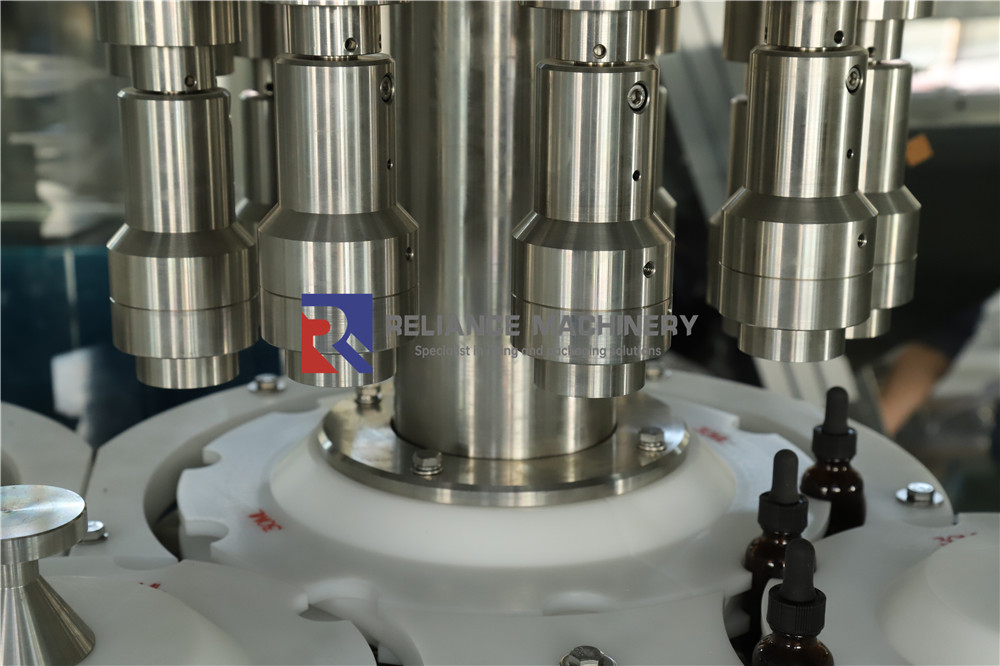

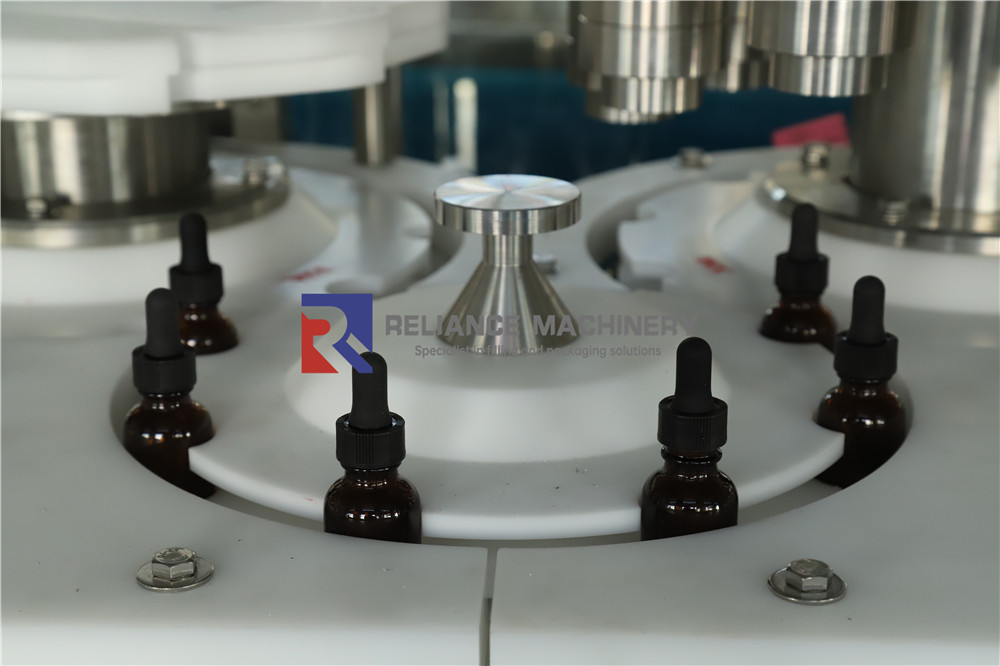

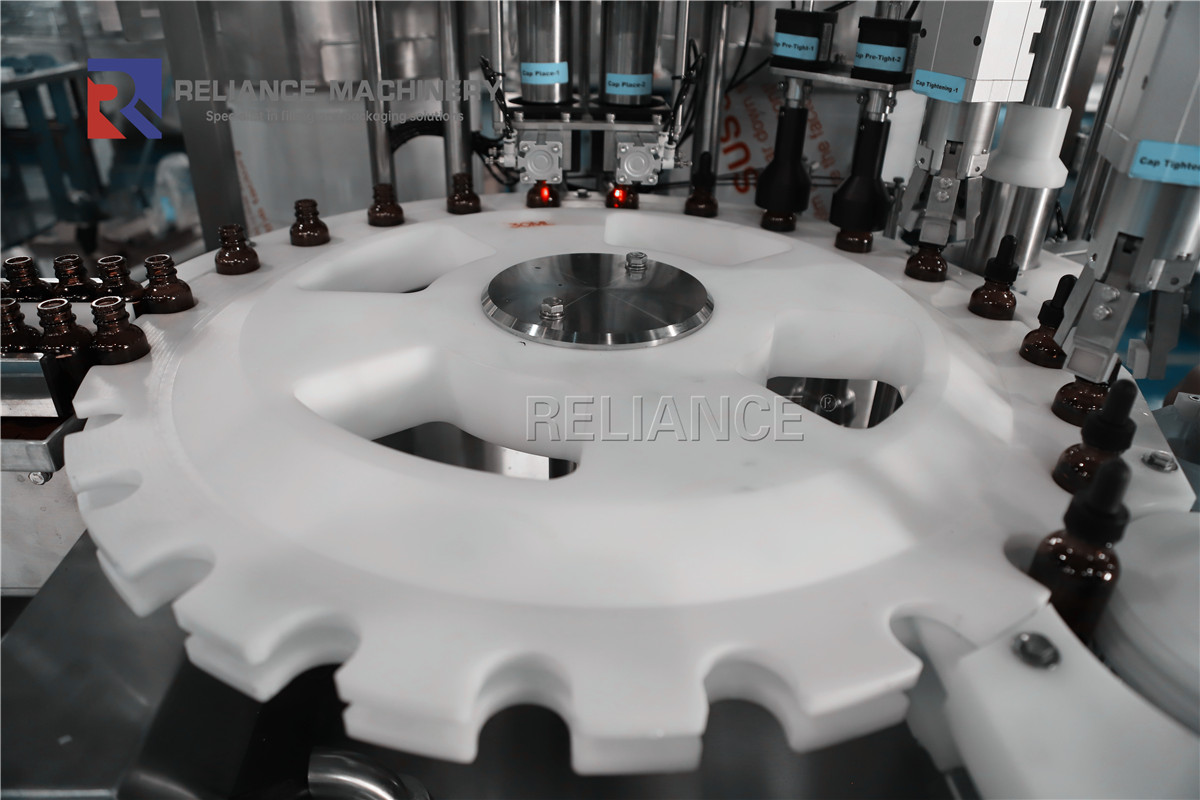

Name: High Speed 12 Head Peristaltic Pump Filling Capping Machine CBD Oil/Hemp Oil/ Cannabis Oil/ THC Oil/ Essential Oil

Filling System: Peristaltic Pump

Filling Head : 12 pcs

Filling Speed: 120 - 150 bottle/min

Filling Range: 10- 150ml

Peristaltic Pump high speed filling capping machine in details:

-

RELIANCE Exhibiting at Pack Expo Chicago - Claim your free pass

We Will Be Exhibiting at Pack Expo Chicago - Claim your free pass

-

High precision Whey protein plastic jar wrap around labeling machine

High precision Whey protein plastic jar wrap around labeling machine for health care products

-

High Speed 1ML Reagent Testing Vials Filling Capping Labeling Machine Packing Line

High Speed 1ML Reagent Testing Vials Filling Capping Labeling Machine Packing Line for the pharmaceutical and bio industry, filling speed can meet 80 bottles/min.

-

Automatic Small Scale 4 Piston Pump Oral Solution Filling Capping Labeling Packing Line

Automatic Small Scale 4 Piston Pump Oral Solution Filling Capping Machine for the pharmaceutical and supplement industry.

-

Automatic High Speed Pre-Roll Joint Cone Tube Labeling Machine

Automatic High Speed Pre-Roll Joint Cone Tube Labeling Machine for THC, CBD Cannabis

-

Automatic Collagen Table Amber Bottle Body Shrink Sleeve Labeling Machine

Automatic Collagen Table Amber Bottle Body Shrink Sleeve Labeling Machine, with the function of feed labels, cutting labels, applying and shrink heat seal labels, for pharmaceutical, cosmetic, and nutrition supplements.

#ShrinkMachine #ShrinkSleeveMachine #ShrinkLabelingMachine #CollagenShrinkPacking #AmberBottleShrink #RelianceMachinery