Filler Stoppering Monoblock Machine

Model RVF

DESCRIPTION:

This automatic Model R-VSF is a monoblock machine that can fil, plug/stoppering, and screw cap up to bottles/vials/containers at a time with speeds up from 30 to 90 bottles per minute, performing each of the operations in synchronization on a common frame-all in the small scale of floor space. it's a frequent choice for use in Class 100 clean rooms in the pharmaceutical or cosmetic industry where the efficient use of space is of prime importance.

The R-VSF is PLC-controlled and features a stainless steel exterior and all liquid contact parts of 316L stainless steel which can meet GMP /cGMP/FDA standards. It has a raised sanitary conveyor that transports bottles/vials to and from the filling/plugging/capping area and comes with a no plug/no cap detection system. Optional features include servo-driven torque heads, over/under torque container rejects system, statistical torque value reporting plug/no cap reject system, and makeup/back detection systems.

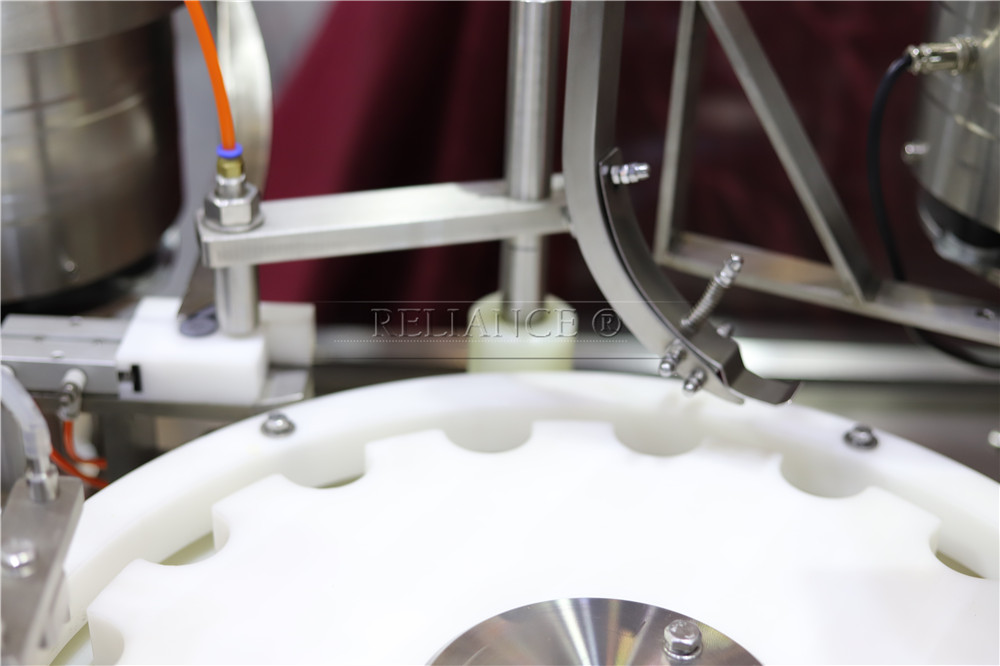

The low profile frame, remote plug, cap pick-up stations, and open flow-through design of the central starwheel are instrumental in enhancing the passage of laminar air flow and minimizing turbulence. The only moving parts over open containers are the filling nozzles. The R-VSF series can handle various container shapes and sizes and a wide range of products from aqueous to heavy oils, suspensions, and creams.

FEATURE:

1. Suitable for small and medium-volume sample experiments in biotechnology, pharmaceuticals, diagnostic reagents, cosmetics and other industries

2. Used for automatic filling and stoppering of vials (full stoppering or semi-stopping)

3. Suitable for water injection, freeze-dried preparations, cells, viruses, proteins and other products

4. Compatible with vials and rubber stoppers of different diameters and heights

5. Compatible with various filling pumps, such as peristaltic pumps, plunger ceramic pumps, etc.

6. Can be installed in sterile laminar flow, isolator, clean bench, safety cabinet, etc.

7. One Set of Container Handling Change parts303/304 Stainless Steel Exterior

8. PLC with Panel View Siemens 700IE HMI

9. 110V/220V single phase / 50-60 Hz

10. Plug and Cap Makeup and Back Up Detection

11. No Plug No Cap Detection

12. Operation and Maintenance Manual, Video training, 24-hour troubleshooting

13. Anti-dripping function filling nozzles

14. Set of SS 316L Custom Designed Nozzles Set of SS 316L Slide Valves and syringes Tygon Intake and Delivery Tubing

15. Plug contact material 316 Stainless Steel pickup rods, Feed Track, Vibratory Feed Bowl, and Collets.

16. Cap Contact material 304 Stainless Steel Pick Up Rods, Feed Track, Vibratory Feed Bowl, Pre-Torque Collet(s), and Torque Collet(s) with Non-Metallic/rubber Inserts.

SPECIFICATION:

1. Capacity: 30-90 bottles/min

2. Filling Volume: Recommended 30-1000ml

3. Filling Accuracy: ±0.5% - ± 1%

4. Power Supply: 220V/ 110V / 50-60Hz / single phase

5. Power Supply: 2.5 KW

6. Dimensions: 2400 (L) x 1300 (W) x 1750 (H) mm

7. Weight: 950 kg

OPTIONAL:

1. Optional online IPC weighing and measuring system;

2. Optional nitrogen filling function (before filling, during filling, after filling, before plugging);

3. Optional isolator.

4. Spare Parts Kit

5. Reject Station

6. Container Makeup and Back Up DetectionFront Panel Electronic Fill Volume Adjustment

7. Filler pass System

8. Servo Driven torquing Heads

MACHINE VIDEO:

APPLICATION:

Medicated oil, balm oil, massage oil, beard oil, tincture, serum, CBD oil, hemp oil, cannabis oil, cosmetic oil, hair oil, liquid drops, and zinc supplements.

- 2024-11-14

- 2024-10-25

- 2024-10-21

- 2024-09-24

- 2024-09-12