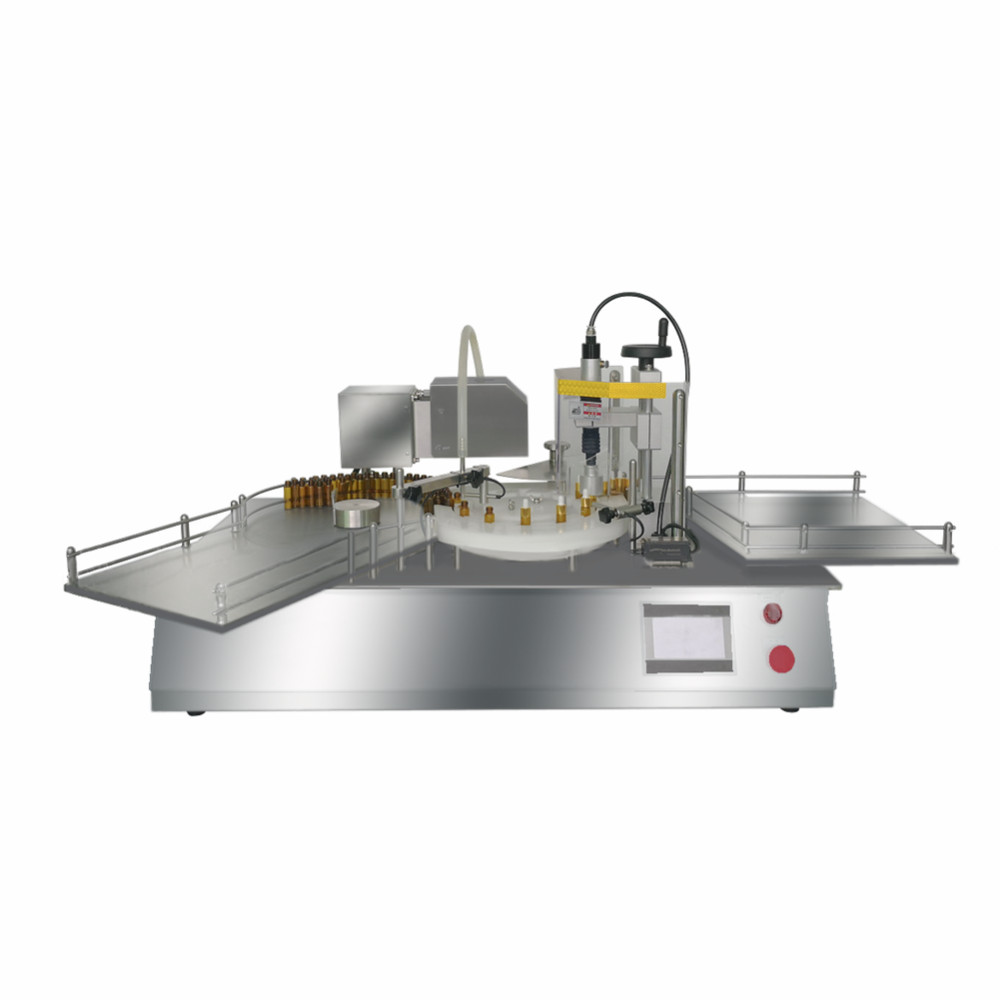

Table Top Bottle Filler Capper Machine

DESCRIPTION:

RELIANCE RVF/T Series versatile table-top semi-automatic gear pump filling machine offers flexibility and versatility to meet all your needs, suitable for all kinds of liquids from fills free- flowing to medium-viscosity products.

A tabletop bottle filling and capping machine is a compact and semi-automatic device designed to efficiently fill bottles with liquids and cap them. It's typically utilized for small-scale production or laboratory settings where space is limited. These machines offer adjustable fill volumes and various capping mechanisms to accommodate different bottle sizes and types of caps. They are commonly used in industries such as pharmaceuticals, cosmetics, food and beverages, and research labs. While they require some manual intervention for bottle placement and operation, they provide a cost-effective solution for small to medium production runs. Overall, tabletop bottle filling and capping machines offer convenience, versatility, and efficiency for packaging needs in constrained spaces.

KEY FEATURES:

1. Functionality: It fills bottles with liquids and caps them, providing a complete packaging solution.

2. Size: Compact and tabletop-sized for easy placement in small workspaces.

3. Capacity: Usually suitable for small to medium production runs, depending on the specific model.

4. Automation Level: Semi-automatic, meaning it requires some manual intervention for bottle placement and operation.

5. Features: May include adjustable fill volumes, various capping mechanisms (such as screw caps or snap caps), and easy-to-use controls.

6. Materials: Constructed with durable materials such as stainless steel for hygiene and longevity.

7. Application: Used in industries like pharmaceuticals, cosmetics, food and beverages, and research labs.

8. Cost: Generally more affordable compared to fully automated production line machines.

9. Maintenance: Requires regular cleaning and maintenance to ensure proper functionality and hygiene standards.

10. Customization: Some models may offer options for customization based on specific production needs.

Before purchasing or using such a machine, it's essential to consider factors like your production requirements, the types of bottles and caps you'll be using, and any regulatory standards that need to be met for your industry.

FEATURE:

1. Quick and easy cleaning

2. Quick changeover from manual to automatic function

3. Footswitch for manual mode

4. 2-speed filling operation within the same cycle

5. 2 models: servo-driven with touch screen and electronically controlled with HMI

6. State-of-the-art electronics and controls

7. Small scale and compact, flexible and portable, suit for small and start business

SPECIFICATION:

1. Capacity: 10-30 bottles/min

2. Filling Volume: Recommended 30-1000ml

3. Filling Accuracy: ±1% - ± 2%

4. Power Supply: 220V/ 110V / 50-60Hz / single phase

5. Power Supply: 400W

6. Dimensions: 400 (L) x 305 (W) x 270 (H) mm

7. Weight: 18kg

OPTIONAL:

1. Customized hopper for the material storage

2. Servo drive for the filling pump

3. Conveyor for the semi-automatic filler machine

MACHINE VIDEO:

APPLICATION:

Medicated oil, balm oil, massage oil, beard oil, tincture, serum, CBD oil, hemp oil, cannabis oil, cosmetic oil, hair oil, liquid drops, and zinc supplements.

- 2024-11-14

- 2024-10-25

- 2024-10-21

- 2024-09-24

- 2024-09-12