Material Mixing Tank For Probiotics 1000L

DESCRIPTION:

The stainless steel mixing tank has the functions of stirring and mixing liquid-liquid or powder-liquid, and is a mass production equipment; it can be supplemented by dispersion, emulsification, heating, and cooling functions to meet the needs of different production processes; it can operate for a long time and has stable operation and noise Small, simple to operate, and highly adaptable, it is an ideal multi-functional equipment for mixing, dispersing, etc.

In order to meet the production needs of industrial occasions in different industries, Yikai stainless steel mixing tanks can be customized in a variety of flexible designs to make the equipment more efficient and user-friendly. Stainless steel mixing tanks, liquid washing pots, reaction kettles, vacuum mixing pots, batching tanks, vacuum mixing tanks, emulsifying tanks, storage tanks, emulsifying mixing tanks, liquid preparation tanks, dissolving tanks, concentrated preparation tanks, and emulsification tanks can be customized according to customer requirements. etc.

FEATURE:

Material viscosity:<500,000 cps

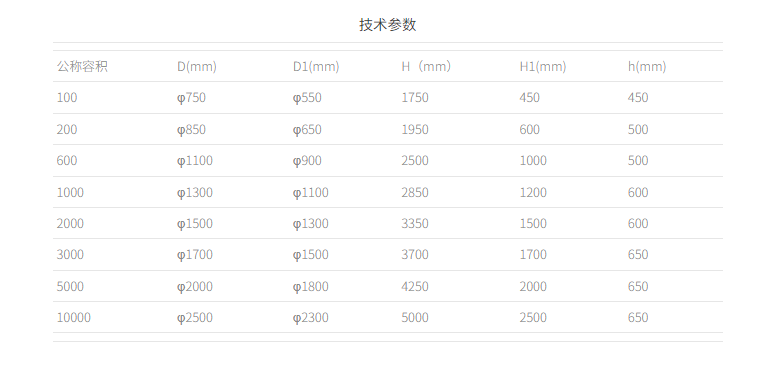

Production capacity: 50-50,000L

Application fields: Suitable for dispersion and mixing of product materials in chemical, biological, lubricating oil, various resin and derivative products industries, etc.

Applicable materials: Various slurries and fluids with material viscosity below 500,000cps and solid content below 60%; such as various personal care, clothing care, chemical emulsions, food sauces, soup stock, pharmaceutical oral liquids and solutions, chemical liquid solvents and more than a thousand kinds of materials.

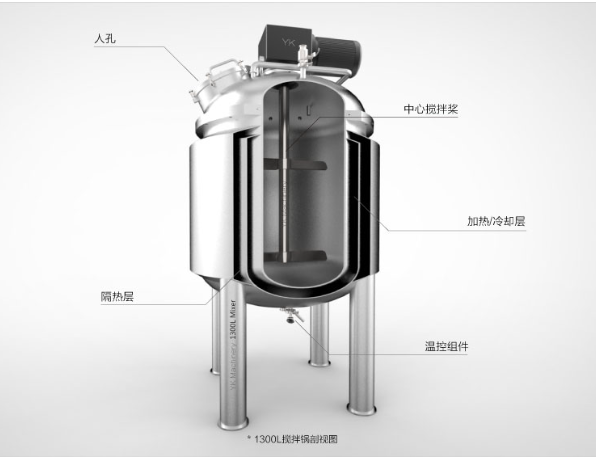

SPECIFICATION:

The structure of the stainless steel stirred reactor provided can be divided into: open flat cover stirring, open butt welding flange reactor and closed reactor: according to the pressure, the reactor can be divided into: normal pressure type, negative pressure type, positive pressure type Type, positive and negative pressure type: According to the heating and cooling method, it can be divided into: jacket type, outer coil type, outer jacket and inner coil type: the mixing method is diversified and selected according to the material characteristics.

Non-standard customization, complete set of line output

Based on non-standard calculations and designs such as customer production capacity, process flow, and process time, the routine is a complete production line.

APPLICATION:

Pharmaceutical, food, cosmetics, health care, and supplements, Nutraceutical.

- 2024-10-25

- 2024-10-21

- 2024-09-24

- 2024-09-12

- 2024-09-12