Automatic Glass or Plastic Bottle Bottom Sticker Labeling Machine

#LabelingMachine #BottomLabeling #BottleBottleLabeling #AutomaticBottomLabeling #RelianceMachinery

DESCRIPTION:

The Glass or plastic bottle bottom labeling machine model RLBT can continuously and accurately label a large number of labels. It is suitable for all kinds of flat-surfaced, side or top of products, such as bottle/jars/cans/containers/ boxes, cartons, plastic bags, aluminum foil bags, paper bags, medicines, cosmetics, skincare products, egg boxes, food, Agricultural products, gift boxes, circuit boards, memory card, industrial batteries, wet tissues, contact lens cases, etc. The top labeler machine for the box model RLBT has the advantages of high productivity and low workforce requirements. Depending on the size of the product/box and the label, it can label 50 to 100 pcs boxes per minute. The high-performance stepping motor achieves precise positioning and labeling in a short time, and the signal conveys the precise angle and speed. The programmable controller executes the labeler’s full automation and digital logic to achieve the synchronous operation performance of the mechanism and uses a microcontroller to achieve high stability and high precision.

Box/Bottle top Bottom labeling as the name implies in the upper plane of the box label, we recommend the use of an Automatic Flat Top Self-Adhesive Labeling Machine, Whether you are labeling bakery goods, tops of jars, boxes, or lay flat goods like chipboard or books, this equipment is up to the task.

Automatic Box/Bottle top Bottom labeling machine adapts with Siemens PLC control, Omron and LEUZE sensors or Keyence, Mitsubishi Servo motor or delta servo motor. It is easy to control and operate, working stably and at high speed and accuracy. Automatic warning on failures, no bottle no labeling. The labeling machine is suitable for all kinds of objects with plane surfaces, such as boxes, bottles, cans, etc. Widely used in cosmetic, drinks, chemical, medical, food industry, stationery CD, various oil, etc, which can highly improve productivity and product quality.

The Box/Bottle top & Bottom labeling equipment is for the top or bottom surface, flat surface in the labeling like food tray, oil, pharma box, wine, cosmetics box, and so on. The machine with elegant design can be easily operated and maintained by the common worker, who requires no special training in operating this machine. Just give a simple adjustment to produce another product when you want to swap the different kinds of bottle labeling.

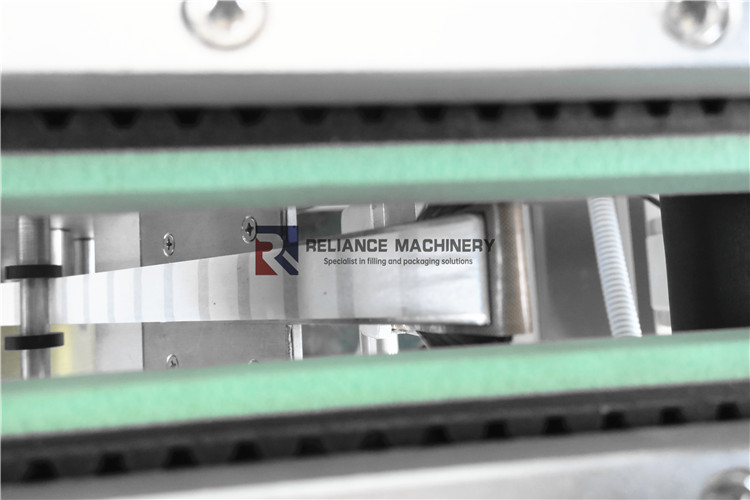

The Box/Bottle top & Bottom labeling is carefully designed to meet all the performance requirements and meets the performance requirements. The top labeler Parts are made from high-grade raw materials including a sturdy stainless steel frame for strong support of the equipment. It works on various types of packaging material therefore ideal for most industries including cosmetic packaging, health care products, retail food, baked goods, and even beverages.

The Box/Bottle top Bottom labeling equipment is easy to set up and run, as well as integrate into other product lines. In summary, the equipment is dependable, consistent, and versatile in usage. It also has good energy-saving features.

| Technical Parameters | |

| Machine Size | 1600(L)×1000(W)×1250(H)mm |

| Output Speed | 20-100pcs/min depends on label and bottle size |

| Height Label Object | 30-280mm |

| Bag size | max L60cm; max W 40cm; max H10cm |

| Label Height | 15-140mm |

| Label Length | 25-300mm |

| Pastes the sign precision | ±1mm |

| Roll inside | 76mm |

| Roll Outside Diameter | 300mm |

| Power Supply | 220V 0.8KW 50/60HZ |

| Power Supply | 2800(L)×1650(W)×1500(H)mm |

| Weight of Labeling Machine | 450Kg |

COMPOSITION AND STRUCTURE:

1. Bracket: supports the entire equipment and work surface.

2. Adjustment device: The labeling position, height, and angle can be adjusted to meet different labeling needs.

3. Slitting device: After slitting the label, it enters the labeling setting area.

4. Sensor: It can sense the surface of the object, control the automatic labeling, automatically determine whether the label is adhered in place, and ensure the flatness and accuracy of label pasting.

5. Control system: controls the operation, labeling speed, and accuracy of the entire equipment.

WORKING PRINCIPLE:

(1) During label delivery, the label is taken out of the label library by the robot and passes through the slitting device, where it is cut into independent labels and prepared for placement.

(2) The labeled object enters the label loading area. After the sensor detects that the object is in place, it automatically detects the position and size of the object.

(3) The control system will automatically fine-tune the adjustment device to make the label fit the surface of the object being attached. After the label is attached to the item, the sensor detects the fit and determines whether the label is in place.

(4) Once the bonding is completed, the sensor will send an execution command to the controller, and the label feeding and loading work will stop. After the labeling work is completed, the manipulator will lift up and wait for the next cycle to send labels again.

(5) During the entire working process, the control system will continuously recalculate the position of the item and the adhesion of the label so that the label fits the item as closely as possible.

FEATURE:

1. The height of the angel of the labeling machine can be adjustable

2. The conveyor and labeling speed can be adjustable

3. PLC control, easy to operate, LED screen, easy to read the labeling times

4. Easy to change labels in different sizes and dimensions

5. Small compact design suit for small capacity products and lab use

6. All built with 304 Stainless steel

7. Provided with 10-30 sets of memory to save parameters from different production lines and is convenient to adjust various productions.

8. Active detection system gives the alarm and the machine stops working when out of carbon fiber tape

9. Smart detection system for missing labeling to guarantee labeling quality

SPECIFICATION:

1. Speed: 30-50pcs/min

2. Labeling width: 10-100mm

3. Labeling length: 20-300mm

4. Accuracy: ±1mm

5. The labeling head is driven by a stepper motor or servo motor

6. Label reel: (ID) 76mm (OD)300mm

7. Power requirement: Single phase, 110 or 220 VAC, 50/60Hz

8. Machine dimension: (L)2001 mm (W)803mm (H)1700mm

9. Overall dimensions: (L)1800 mm x (W)1000mm x (H) 1350mm

10. Machine weight: 650Kg

OPTIONAL:

1. Hot Stamp (Lot/Date Coding)

2. Missing Hot Stamp Imprint Check

3. Integrated Thermal Printer (Lot/Date, Bar Code and Graphics)

4. Dataflex or Similar Lot/Date Code Printer

5. Clear, Metalic or Color Label Sensor

6. End to end Transfer Plates

7. Infeed and outfeed Conveyor Extensions

8. Separator Wheel for Controlled Spacing

9. Automatic feeding & collection turntable (driven by a motor)

10. Conveyor belt lengthening at the entrance and exit ends

11. There is no printing detection, and there is no printing detection and shutdown.

MACHINE VIDEO:

- 2024-10-25

- 2024-10-21

- 2024-09-24

- 2024-09-12

- 2024-09-12