30ML Probiotic Liquid Amber Glass Dropper Bottle Water Washing Cleaning Machine

#BottleWashingMachie #BottleCleaningMachine #AmberBottleWashingMachine #ProbioticLiquidBottle #RelianceMachinery

DESCRIPTION:

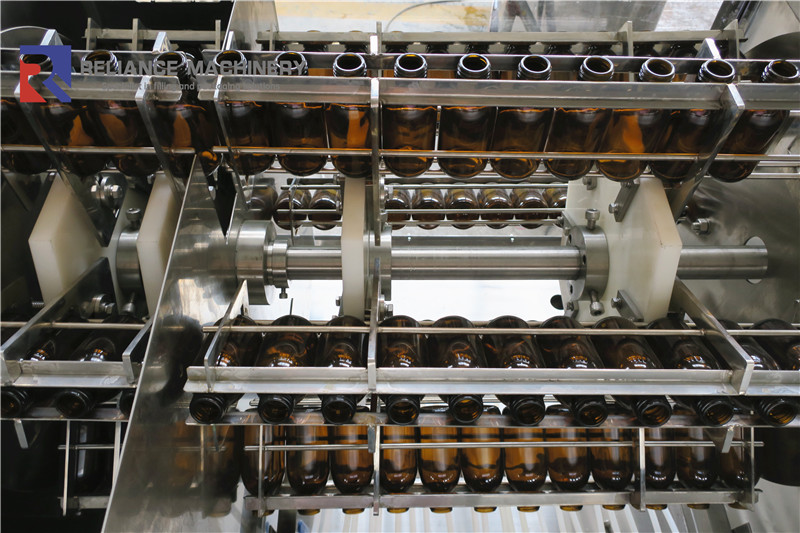

Pharmaceutical 30ML Probiotic Liquid Amber Glass Dropper Bottle Water Washing Cleaning Machine is composed of a Dia 900mm rotary-type feeding turntable, the bottle gets into the washing position by the transfer channel conveyor, This machine can store the bottle, buffering the bottle, and change the bottle flow direction. It can connect with the filling line, starting with washing-filling-stoppering -capping- and labeling-packaging. It is suitable for washing bottles with the minimum use of labor & time. The machine provides water washes & air washes for the perfect washing of small glass bottles. The machine is widely used in the cosmetic, CBD oil, and pharmaceutical industries and is the preferred choice for amber glass bottle filling line operations.

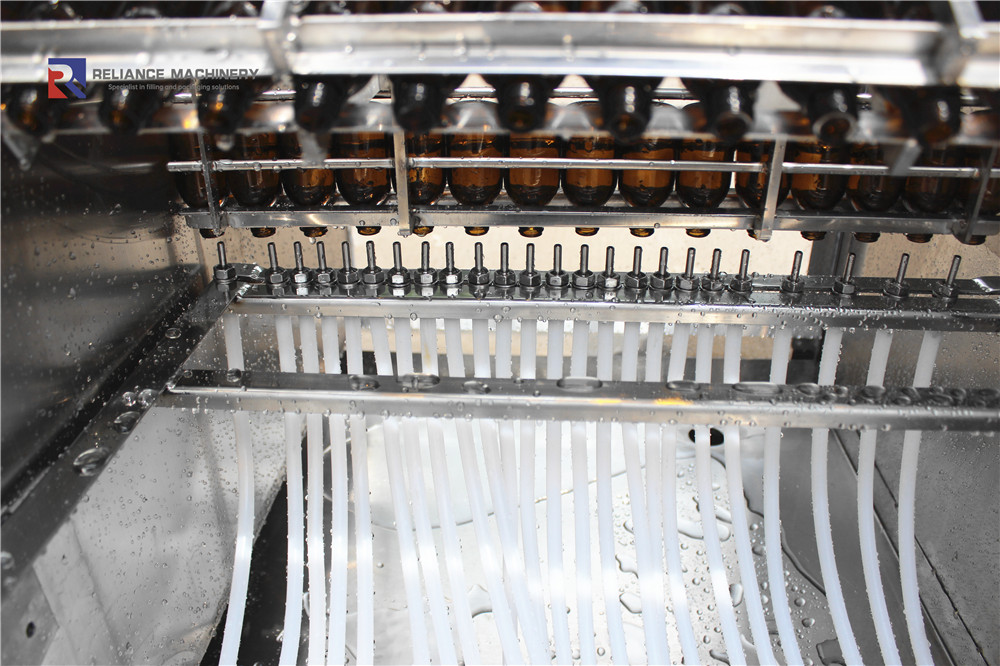

Containers feed on the feeding turntable. An in-feed worm inverts container /glass bottles to neck down position and feeds them through a specially designed indexing device. The device carries the container forward and stops. The nozzle carrier enters into the container and activates the jet of water/air. The air/water flow is deactivated after the washing cycle is over. The device indexes the vials/bottles for the next wash. A separate pumping station gives the right quantum of water at the desired pressure. Washed containers are again inverted to neck upward position to collect in the outfeed tray/directly feed to next equipment, such as glass bottle filling machine.

FEATURE:

1. All contact parts are made from high-quality Stainless Steel 316L and argon arc welded

2. All exposed parts are made from Stainless Steel 304/hard chrome plated/brass for corrosion free long life

3. The unit is built on an SS Square pipe frame and totally encompassed with SS Coverings

4. The washing section is totally covered with acrylic cabinet

5. “No Container - No Washing” system

6. “No washing - No water supply” system

7. Low water consumption

8. Quick change over with minimum use of tools

9. Variable AC frequency drive for speed adjustment

10. Digital counter for counting production output

11. Fixed top nozzles at each washing station to ensure external washing of vials/bottles at the same time as internal washing

12. The flow of washing Media stop during the indexing of the chain saves utilities

13. Easily cleanable & Inter changing facility

SPECIFICATION:

|

Turn Table |

|

|

Turn Table Dia |

φ720 |

|

transfer capability |

Synchronized with Washing machine |

|

Power Supply |

220V 50HZ |

|

Power |

0.12KW |

|

Outside Dimensions |

750×1200×950 |

|

Washing Machine |

|

|

Production Capacity |

40-50bottle/ min @ 100ml vial. |

|

Power |

1.5 Kw |

|

Compressed Air Consumption |

15m3/h,0.3~0.4kg/cm2 |

|

Water Consumption |

0.6~1t/h |

|

Outside Dimension |

1380×900×1350 |

OPTIONAL:

1. ultrasound system for bottle cleaning

MACHINA VIDEO:

APPLICATION:

Pharmaceutical, food, cosmetics, health care, and supplements, Nutraceutical.

- 2024-11-14

- 2024-10-25

- 2024-10-21

- 2024-09-24

- 2024-09-12