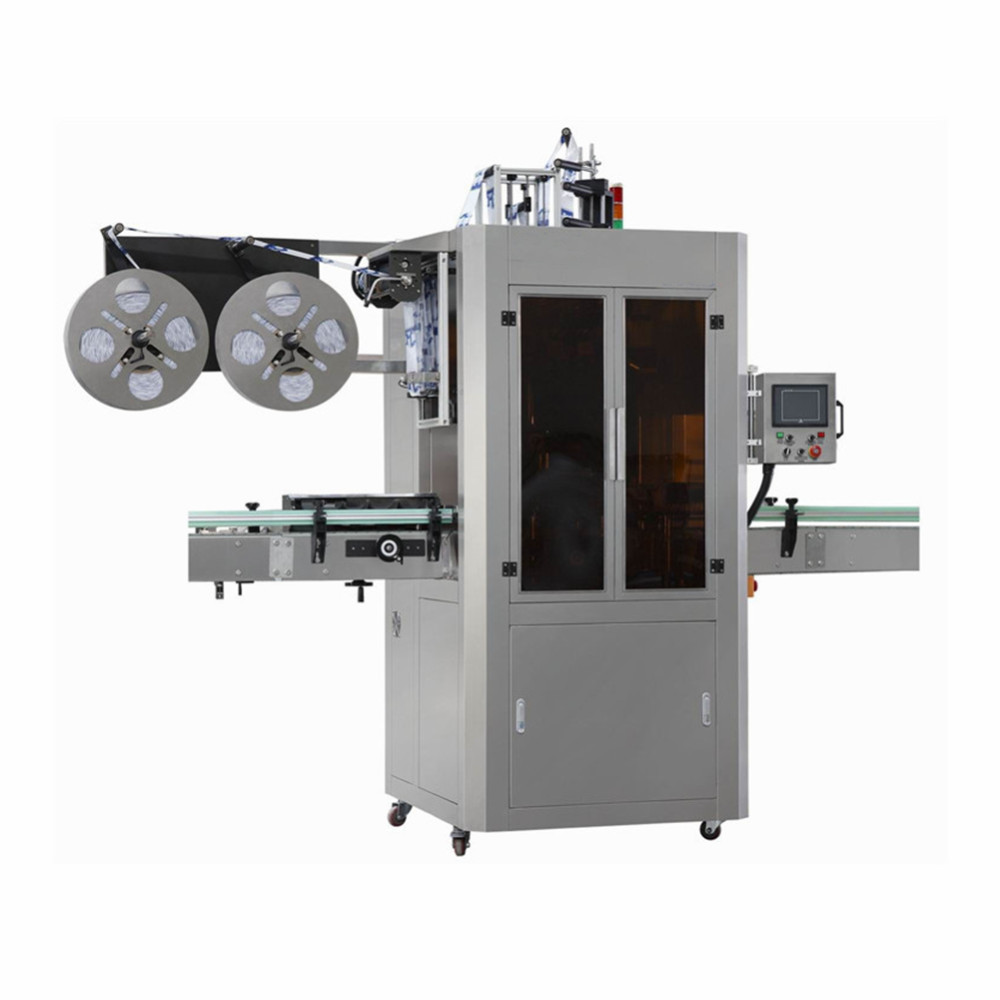

Automatic Vertical Probiotic Amber Glass Bottle Dropper Cap Shirnk Sleeve Labeling Machine

#ShrinkSleeveLabeling #VerticalShrinkLabelingMachine #AutomaticShrinkLabeling #ProbioticDropperBottleBankShrink #RelianceMachinery

DESCRIPTION:

RELIANCE Model RSLB Automatic Vertical Probiotic Amber Glass Bottle Dropper Cap Shirnk Sleeve Labeling Machine, as one of the equipment with high technical content in post-packaging, the sleeve labeling machine is mainly used in food, beverage, and pharmaceutical industries, condiments, juices, injection needles, milk, refined oil, and other fields. Principle of sleeve labeling: When a bottle passes through the bottle detection sensor on the conveyor belt, the servo-controlled drive group will automatically send the next label. At the same time, the brushing wheel group will brush the next label, and the label will be sleeved into the bottle. If the position of the positioning detection sensor is incorrect at this time, the label cannot be smoothly inserted into the bottle.

FEATURE:

1. Machine works Stable and reliable.

2. The servo system drives the machine.

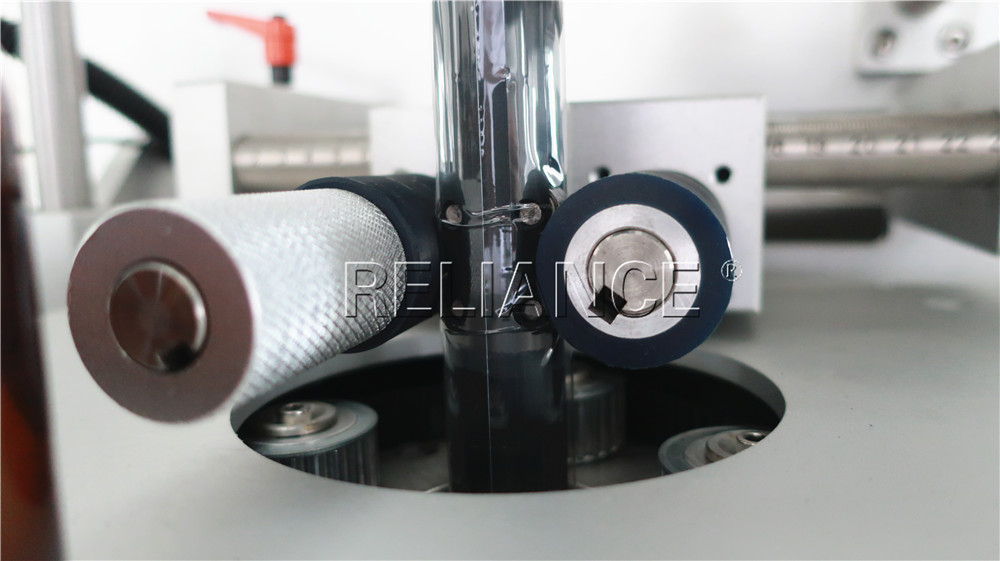

3. Belt driving cutter, quick and easy blade replacement.

4. Easy to change mandrels and bottles separating worms to suit different bottles.

5. No bottles, no sleeve inserting.

6. Mature program makes machines work stably.

7. Innovative machine structure design ensures excellent durability and unmatched structural quality.

8. The speed of the Sleeve inserting into bottles is adjustable and works for more kinds of bottles.

9. The frame is made of 304 stainless steel, no rusting problem.

10. Easy to use touch screen display with job memory

11. Sanitary stainless steel 304SS components

12. Easy changeover with a minimum of part changes

SPECIFICATION:

1. Capacity: 30-100 bottles/min

2. Film: PVC, PET, OPS

3. Film thickness: 0.035 - 0.05 mm

4. Label height: 40-300mm

5. Flat width: Max. 210mm

6. Core of roller: 76mm or 127mm

7. Bottle diameter: φ22 to φ125

8. Bottle height: Max 330mm

9. Material of bottle: Glass, metal, plastic

10. Power Supply: 220 VAC; 50/60Hz; 3 phase or 380 VAC; 50/60Hz; 3 phase ( 2.5 Kw)

11. Dimension: (L) 2000mm (W)845mm (H)2000mm

12. Weight: 650kg

SHRINK SLEEVE LABELS:

Printed shrink labels are a great way to add high-impact color messages to your container. In many cases, the only way to economically label custom containers with aggressive contours is with a sleeve labeling system. Labels come in a variety of types such as PET, PLA, PVC, and OPS. Sleeve labels can also be used as tamper-evident seals complete with perforations for easy removal. They can also be used to form multi-pack bundles. No other labeling method provides as wide a range of color, detail, and application options as a Shrink Sleeve Label

|

Type: |

PVC LABELING MACHINE |

Applicable Industries: |

Manufacturing Plant, Construction works |

|

Showroom Location: |

United States |

Condition: |

New |

|

Application: |

Beverage |

Packaging Type: |

Bottles |

|

Packaging Material: |

Wood |

Automatic Grade: |

Automatic |

|

Driven Type: |

Electric |

Voltage: |

380/220VAC |

|

Place of Origin: |

Shanghai, China |

Brand Name |

Shanghai Reliance Machienry |

|

Dimension(L*W*H): |

L2100mm *W850mm *H2000mm |

Weight: |

300 KG |

|

Warranty: |

1 Year |

Key Selling Points: |

High-accuracy, servo control, servo control |

|

Machinery Capacity: |

80 sets/month |

Machinery Test Report: |

Provided |

|

Marketing Type: |

New Product 2022 |

Warranty of core components: |

1 Year |

|

Video outgoing-inspection: |

Provided |

After-sales Service Provided: |

Field installation, commissioning and training |

|

Core Components: |

PLC, Motor, Engine, Pump |

Bottle type: |

Round Square Flat Pet plastic and glass Bottle |

|

Product name: |

Auto Shrink Sleeve Labeling Machine |

Function: |

PVC Shrink Sleeve Label Cutting Machine |

|

Usage: |

Sleeve Label |

Material: |

304/316 Stainless Steel |

|

Labeling speed: |

100-150(Bottle/min) |

Model: |

RSLB |

|

Advantage: |

Widely Used, high speed, high quality |

PRINCIPLE:

The principle of the automatic bottle shrink sleeve labeling machine is as follows: when the bottle-pushing electric eye finds that there is a bottle coming and thinks that it is necessary for continuous production, the bottle-feeding screw starts to push the bottle (the function of the bottle-feeding screw is to bring the bottles that are not equidistant from the beginning to the new equidistant) Bottles enter the core unit of the sleeve labeling system. When the sleeve label electric eye senses that there is a bottle coming, it immediately transmits the information to the control center PLC, and through the PLC, four instructions are sequentially and continuously issued: label delivery, positioning, cutting Labeling and shooting, when the shooting is over, the full-screen labeling process of a bottle area is completed, and then enters the label finishing and shrinking element

HIGH LIGHTS

1. The products on the line are spaced with an endless screw.

2. A micro-perforation is set in between each sleeve.

3. The sleeve is opened after the perforation and thrown onto the

container while it is moving on the conveyor.

TECHNOLOGY

1. Mechanical perforator maintenance-free.

2. Brushless drivers for the tubing’s running and the sleeve’s separation and application.

3. Few moving parts for low maintenance time and expenses

4. The operator’s working station is optimized to ease his duty

BENEFITS

1. The perforator is compatible with any length flat width (lfw), while avoiding any loss on the tubing which prevents any loss of time.

2. The sleeves are opened and shaped according to your very product’s shape: the lfw is perfectly fitted (no material loss and easier shrinking) and the sleeve position is optimized.

|

Items |

Electric |

Models |

Qty |

Brand |

origin |

|

Table lift up &down |

AC Motor |

5IK90GU-CF-25KB |

1 |

ZD |

Taiwan |

|

Label rushed down |

AC Motor |

5IK120A-CF |

1 |

ZD |

Taiwan |

|

Labels feeding unit |

AC Motor |

RV50-15K-180 |

1 |

SANI |

Taiwan |

|

Frequency transducer |

ATV12H018M2 |

1 |

SCHNEIDER |

France |

|

|

Photosensor |

CX-421 |

1 |

SUNX |

Japan |

|

|

Bottles keeping belt |

AC Motor |

5IK90GN-SF-5GN12.5KW |

1 |

ZD |

Taiwan |

|

Frequency transducer |

ATV12H018M2 |

1 |

SCHNEIDER |

France |

|

|

Bottles separating |

AC Motor |

5IK90GN-SF-15K |

1 |

ZD |

Taiwan |

|

Frequency transducer |

ATV12H018M2 |

1 |

SCHNEIDER |

France |

|

|

Brush unit |

AC Motor |

4IK25GN-C-4GN 0.75K |

2 |

ZD |

Taiwan |

|

Cutter unit |

Knife disc motor |

BCH0801*1*1*1C (400W) |

1 |

Panasonic |

Japan |

|

Knife disc servo |

LXM23DU04M3X (400W) |

1 |

Panasonic |

Japan |

|

|

Photosensor |

PM-L44 |

2 |

SUNX |

Japan |

|

|

Driving unit |

Motor |

BCH0801*1*1*1C (750W) |

1 |

Panasonic |

Japan |

|

Servo |

LXM23DU04M3X (750W) |

1 |

Panasonic |

Japan |

|

|

Electric eyes |

Fiber sensor |

FX-301 |

1 |

SUNX |

Japan |

|

Bottles sensor |

Sensor |

CX-442 |

1 |

SUNX |

Japan |

|

Conveyor |

Frequency transducer |

ATV12H075M2 |

1 |

SCHNEIDER |

France |

|

Motor |

RV50-25K-0.75KW |

1 |

SANI |

Taiwan |

OPTIONAL:

1. Transparent label sensor

2. Date and batch number coder/printer

3. Printer Bracket

4. Customized guide rail

5. Customized conveyor

6. Feeding and collection table

MACHINE VIDEO:

APPLICATION:

Medicated oil, balm oil, massage oil, beard oil, tincture, serum, CBD oil, hemp oil, cannabis oil, and cosmetic oil, hair oil.

- 2024-11-14

- 2024-10-25

- 2024-10-21

- 2024-09-24

- 2024-09-12