High Speed Probiotic Liquid Drop Amber Glass Dropper Bottle Filling Capping Machine

#HighSpeedDropperFillingMachine #ProbioticLiquidFillingCapping #HighSpeedMonoblockFillingMachine #RotaryMonoblockFillingCapping #RelianceMachinery

DESCRIPTION:

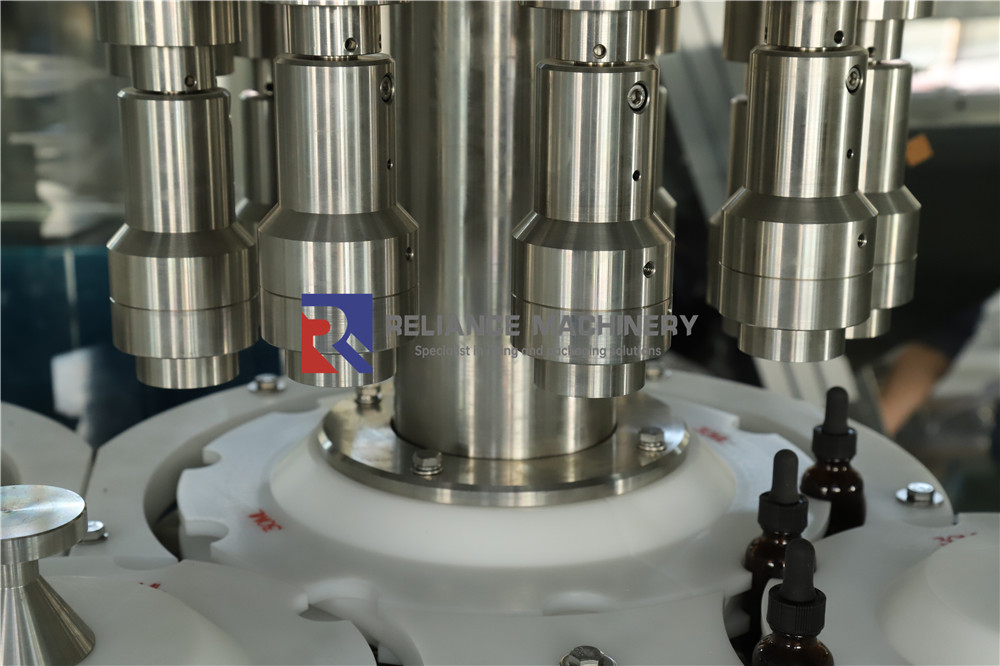

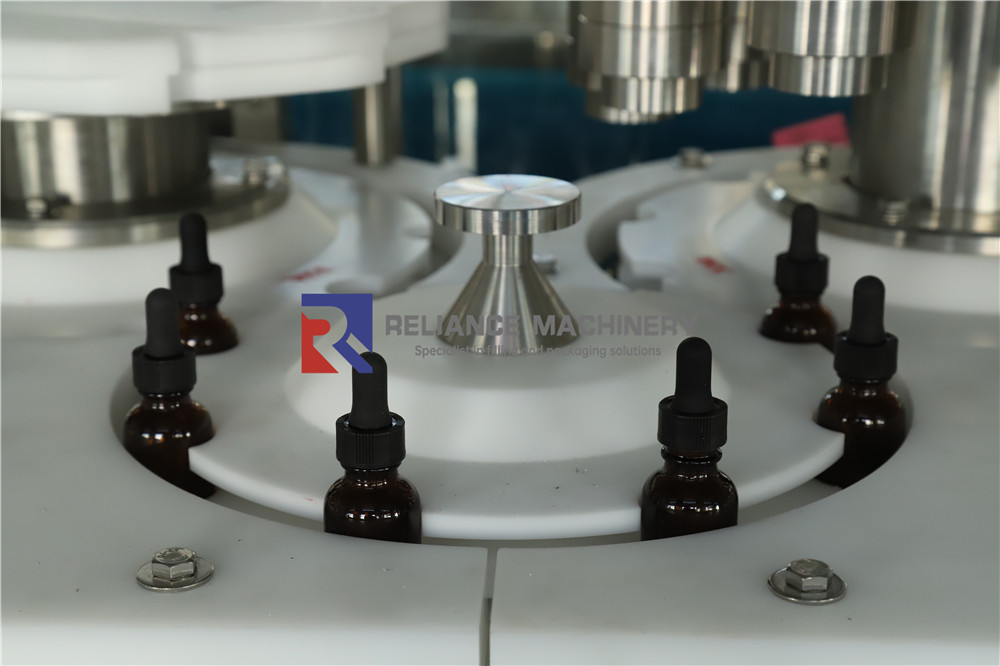

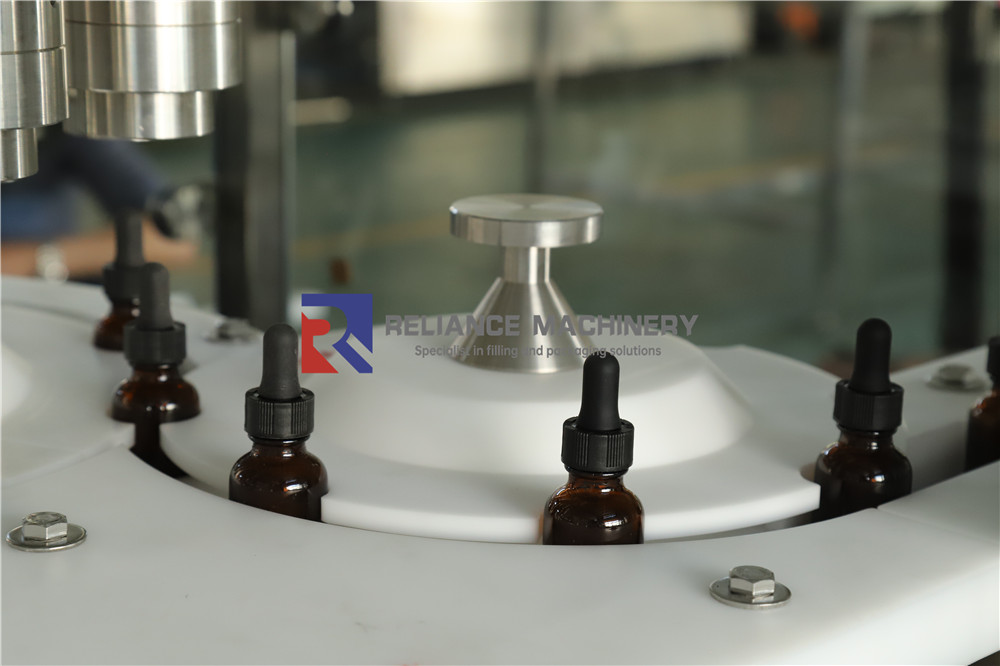

RELIANCE RVFR High Speed Rotary Type Monoblock liquid Amber Glass Dropper Bottle filler and capper Machine design for the 1Oz to 4Oz Probiotic Liquid Drops ( Cosmetic Serum, Herbal Oil, Essential Oil, Sweet Oil, Hair Oil, Perfume Oil, Organic Oil, Cannabis Oil, CBD Oil, THC Oil, Tea Tree Oil, Mineral liquids, Liquid Zion, Liquid Calcium, Liquid Magnesium for woman and kids) adapts high-performance servo technologies used in filling station and capping station, that provides fast, precise probiotic liquid filling and capping. During the liquid filling process, bottles are carried through the filling area by servo-driven feed screw, and the liquid filling nozzles are mounted on a walking beam mechanism, which allows tracking the movement of bottles for diving-type filling in continuous motion. Once the filling process is complete, the filled bottles will continuously travel to the rotary capping system. High speed liquid filling and capping jobs are accomplished in one machine, the capacity of monoblock machine can reach to 120 - 150 bottles/minute.

The machine does not require any change parts for change in Fill Volume with Servo Drive Technology, which helps the user to set the required fill volume directly from the Machine control panel Touch Screen system. Machine new technology also offers simple user-friendly operation with few moving parts coming in contact with liquid and also a higher level ofaccuracy for filling liquid.

The high-speed 4 oz glass dropper bottle filling and capping machine is an automated equipment designed for the rapid and precise filling and capping of glass dropper bottles. It is commonly used in industries such as pharmaceuticals, cosmetics, and food, where efficient and accurate filling and capping processes are required.

1. High-Speed Operation: This machine is designed for high-volume production environments, capable of quickly completing the filling and capping process.

2. Precision: It employs highly accurate filling and capping technology to ensure the precise volume of liquid in each bottle.

3. Automation: The equipment typically features automation capabilities, handling everything from bottle loading to filling and capping to unloading with minimal manual intervention.

4. Capacity Range: These machines can typically accommodate glass dropper bottles of various capacities, ranging from a few milliliters to several ounces.

5. Ease of Adjustment and Maintenance: They are designed to be easy to adjust and maintain, ensuring that different bottle sizes can be processed on the same machine.

6. Hygiene Standards: Usually, these machines comply with industry-specific hygiene and safety standards to ensure the purity of the filled liquids

7. Versatility: Some machines may have multi-functionality, accommodating different types of liquids and bottle designs.

The filling system of the cannabis herb liquid :

The filling system for cannabis herb liquid involves the equipment and processes used to accurately and efficiently fill containers (such as bottles, vials, or cartridges) with cannabis-infused liquids.

FEATURE:

1. Affordable solutions without sacrificing quality, power, and service, easy operation and maintenance

2. Quick and easy changeover process for different sizes and shapes of containers

3. Dispenses free-flowing, semi-viscous to viscous, as well as molten products, pastes, and creams

4. Pharmaceutical Industry compliant and cleanroom-ready systems

5. Durable stainless steel structure with GMP or FDA-approved product contact parts

6. HMl touchscreen capabilities

7. Upgrade with automated capabilities

8. IQ / OQ / PQ/ DQ documents offer for custom qualification and validation.

9. No Bottle - No Fill System, No Bottle Machine Stop System

10. Rotary Bottle Movement system for smoother operation

11. All contact parts are made of SS316 material with an easy removal system

12. Very High Fill Accuracy of +/- 0.5% to +/-1%

13. Built-in A.C. Variable Freq. Drive System

14. No Cap on Bottle - Machine Stop System

15. Safe door open, machine stop

SPECIFICATION:

1. Bottle Diameter: 16mm to 50mm* Bottle Height: 50mm to 200mm*

2. Cap Size: 18mm to 55mm ROPP or Plastic Screw Cap

3. Fill Range: 10ml -120ml ( 1Oz to 4 Oz)

4. Accuracy : +/- 1ml on Standard Machine or Optionally +/-0.5ml available on request.

5. Power: 4.5KW / 110V / 220 VAC Single Phase 50/60Hz

6. Capacity: Max. 120 - 150 Bottles per minute depending on Fill Volume and Type of Liquid

7. Conveyor Height: 850-900 mm

8. Dimensions : 4500 mm (L) x 1500 mm (W) x1750mm(H)

OPTIONAL:

1. Customized hopper for the material storage

2. Servo drive for the filling pump

3. Anti-dripping filling nozzles

4. Guiding system for the bottleneck

5. Convery feeding for special shapes of containers

Filling System / Pumps Optional:

These Complete Turnkey Solutions can accommodate a wide variety of liquid products as well as different pump options:

1. Piston Pumps

2. Peristaltic Pumps

3. Gear Pumps

4. Ceramic Pumps

MACHINE VIDEO:

APPLICATION:

Medicated oil, balm oil, massage oil, beard oil, tincture, serum, CBD oil, hemp oil, cannabis oil, cosmetic oil, hair oil, liquid drops, zinc supplement, Cosmetic Serum, Herbal Oil, Essential Oil, Sweet Oil, Hair Oil, Perfume Oil, Organic Oil, Cannabis Oil, CBD Oil, THC Oil, Tea Tree Oil, Mineral liquids, Liquid Zion, Liquid Calcium, Liquid Magnesium for woman and kids

- 2024-11-14

- 2024-10-25

- 2024-10-21

- 2024-09-24

- 2024-09-12