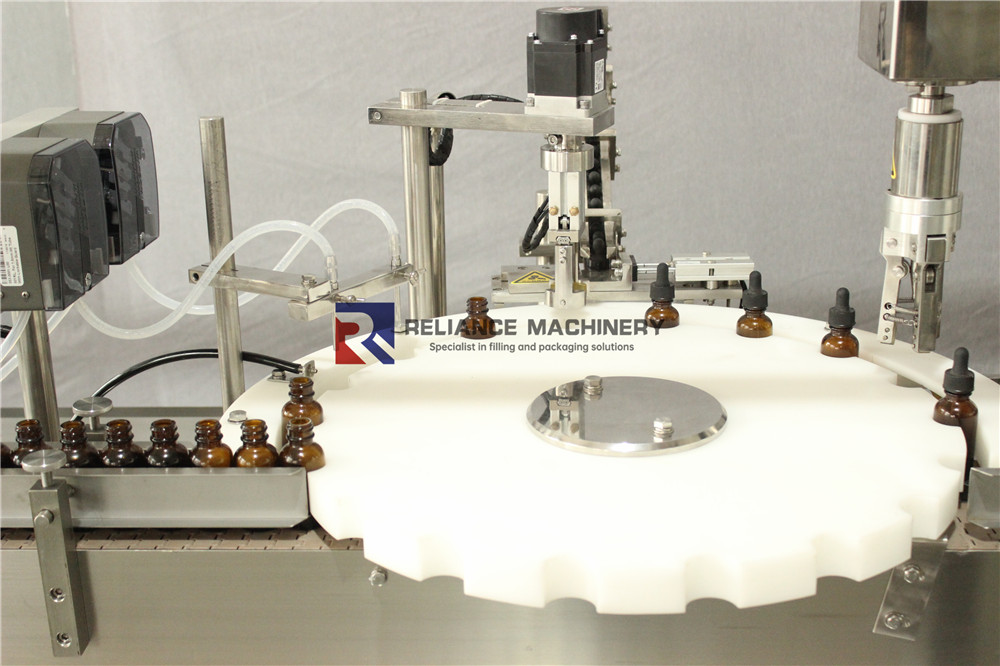

Glass Dropper Bottle Filling Capping Machine

DESCRIPTION:

The automatic glass dropper bottle filling and capping machines, particularly monoblock systems, have revolutionized the packaging process for various industries such as pharmaceuticals, CBD oil, medical oil, and cosmetics. These machines, such as the ones manufactured by Reliance Machinery, are specifically designed to automate the filling and capping of liquid products into glass dropper bottles, ensuring precision, efficiency, and product integrity.

A monoblock glass dropper bottle filling and capping machine combines multiple functions into a single integrated system. It typically consists of a conveyor system that moves the bottles through different stations, including filling, cap placement, and capping.

The filling station of the machine accurately dispenses the liquid product into each glass dropper bottle, ensuring consistent and precise dosing. These machines often utilize volumetric or piston-filling systems to achieve accurate and reliable results.

After the filling process, the cap placement station securely positions the dropper caps onto the bottles, while the capping station applies the necessary torque to ensure a tight seal. This prevents leakage or contamination of the product.

Reliance Machinery is a well-known manufacturer of packaging machinery, including glass dropper bottle filling and capping machines. Their machines are known for their high-quality construction, advanced technology, and user-friendly operation. They offer reliable and efficient solutions for filling and capping glass dropper bottles, meeting the specific needs of various industries.

FEATURE:

1. Diving type: Servo System

2. 1 to 12 heads filling pump stations according to the speed required.

3. Piston pump, Ceramic pump, and peristaltic pump as optional

4. Application for different sizes and shapes of bottles by changing parts

5. Various speed settings of liquid filling.

6. Easy to Clean and fast Changeover

7. High filling accuracy which can meet ±0.5% to ±1%.

8. Simple and quick tech mode setup.

9. Track full / track empty sensors tell the machine to stop or re-start

10. Bottle mouth holder design for special applications

11. Siemens PLC control with user-friendly operation, Touchscreen Display, and Easy to Navigate Menu

SPECIFICATION:

|

Model |

RVF 30 |

RVF 60 |

RVF 120 |

|

Output |

30 upm |

60 upm |

120upm |

|

Filling Accuracy |

+/- 1% |

||

|

Filling Pump |

Piston Pump, Peristaltic Pump, Ceramic Pump |

||

|

Filling Range |

10ml -120ml/ 1Oz to 4Oz |

||

|

Suitable |

Plastic Boston Bottle/ Glass Boston Bottle |

||

|

Electricity |

1.8 KW @110V/1Ph |

2.5 KW @110V/1Ph |

6KW @110V/1Ph |

|

Air Supply |

50LPM @6bar |

50LPM @6bar |

60LPM @6bar |

|

Dimension (LX W X H) |

2100 x 1450 x 1750 mm |

2400 x 1450 x 1750 mm |

4500 x 1550 x 1750 mm |

OPTIONAL:

1. Liquid buffer/storage tanks.

2. Bottle buffering table

3. Safe door

4. Bottleneck holders

5. Rinser station before filling system station

6. Anti-drip filling nozzles for oils

7. Rejection station

8. Piston pump, Ceramic pump, and peristaltic pump as optional

MACHINE VIDEO:

- 2024-11-14

- 2024-10-25

- 2024-10-21

- 2024-09-24

- 2024-09-12