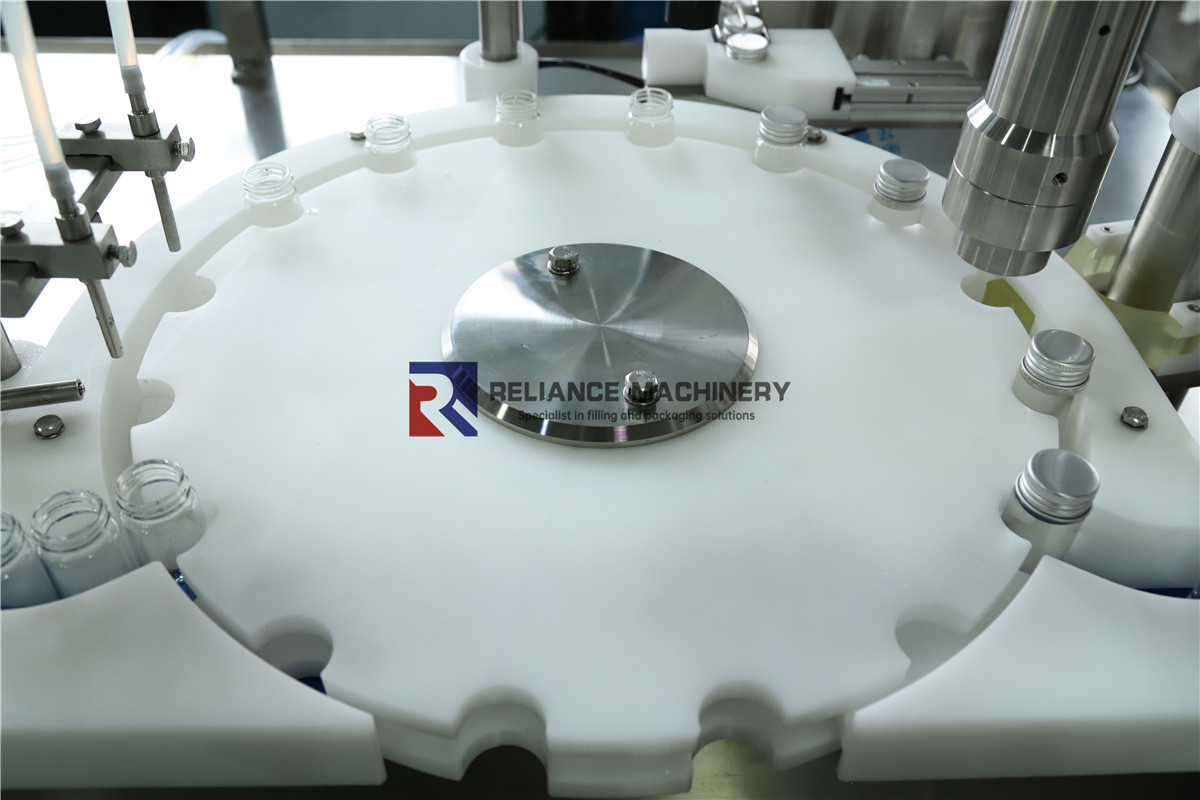

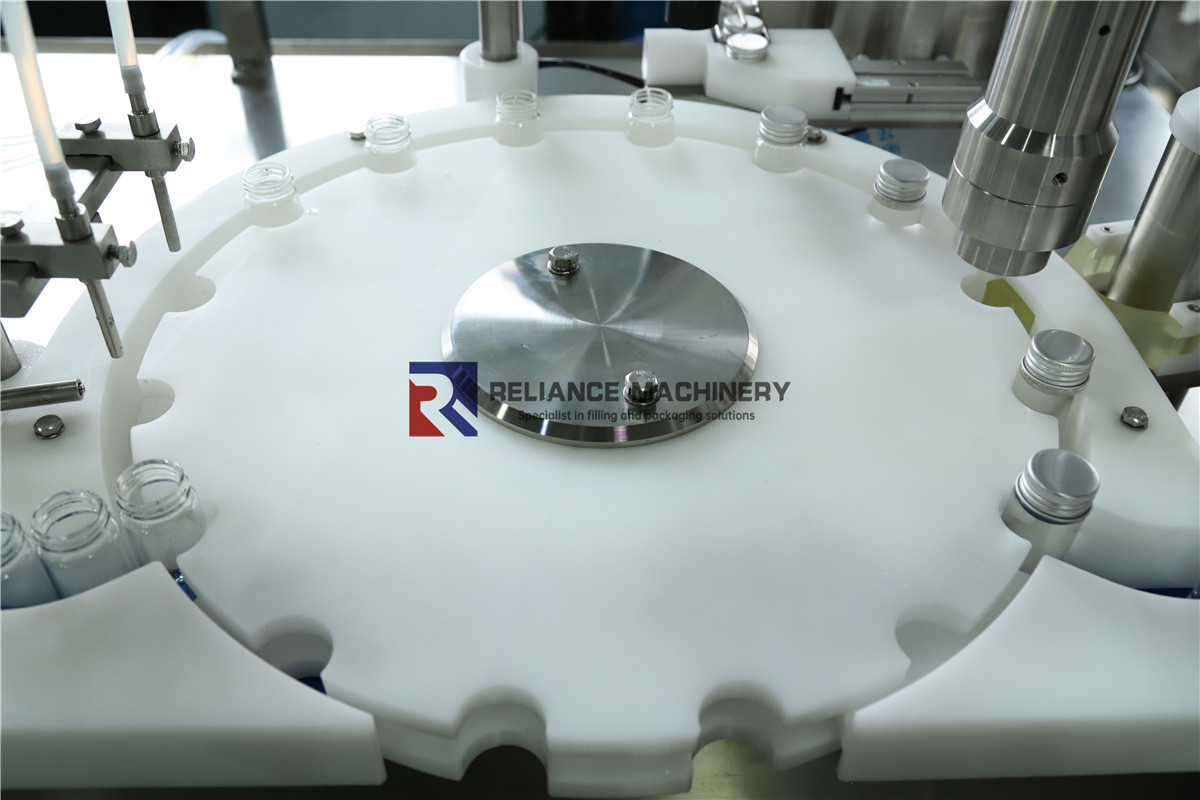

Small Scale 30ML Monoblock Automatic Herbal Medicated Oil Bottle Filling Capping Machine

#MedicatedOilFilling #SmallFillingCappingMachine #HerbalMedicatedOilFilling #30MLFillingCapping #RelianceMachinery

DESCRIPTION:

The Small Scale 30ML Monoblock Automatic Herbal Medicated Oil Bottle Filling Capping Machine For Pharmaceutical, Cosmetic, CBD, Healthcare is specialized industrial equipment designed for efficiently filling bottles/vials/tubes with Green Oil, Flower Oil, Medical oil, Medicated oils, Perfume, Herbal Oil, Massage oil, CBD oil, Essential oil, Hemp oil, Cannabis oil with the function of automatic liquid filling, Metal caps or plastic screw cap pick up and place on then sealing them with screw or aluminum lids. These machines are widely used in Singapore, Thailand, Vietnam, Malaysia, and Indonesia.

SPECIFICATION:

| 1. | Model | RVF |

| 2. | Application | Medical oil, Medicated oil, Message Oil, Essential Oil, CBD Oil, Perfume |

| 3. | Function | Bottle Feeding, Oil Filling, Rollers/Stopper Insert, Cap place on, cap close |

| 4. | Capacity | 30 - 60 - 75 Bottles / Min |

| 5. | Filling System | Peristaltic Pump, Ceramic Pump, Piston Pump |

| 6. | Filling Nozzles | 1 - 6 Nozzles as Optional |

| 7. | Capping Heads | 1 - 2 Heads As Optional |

| 8. | Power | 2.5Kw, 110V - 220V - 380 V, Single Phase / 3 Phase , 50Hz/60Hz |

| 9. | Air Supply | 60 - 90 PSI |

| 10. | Dimension | 2600 x 1350 x 1750 MM ( L X W X H ) |

| 11. | Weight |

750 KG |

CHARACTERS:

1. Diving type: Servo System or mechanical drive

2. 1 to 4 heads filling pump stations according to the speed required.

3. Piston pump, Ceramic pump, and peristaltic pump as optional

4. Application for different sizes and shapes of glass bottles by changing parts, such as round tube bottles, and square glass bottles, oval bottles.

5. Various speed settings of liquid filling, suited for small speeds 30 bottles/min, standard speed 60 bottles/min.

6. Easy to Clean and fast Changeover

7. High filling accuracy which can meet ±0.5% to ±1%.

8. Simple and quick tech mode setup.

9. Track full / track empty sensors tell the machine to stop or re-start

10. Bottle mouth holder design for special applications

11. Siemens PLC control with user-friendly operation, Touchscreen Display, and Easy to Navigate Menu

12. Motorized single-lane sanitary conveyor. customized conveyor lengths are available upon request.

13. Type 304 stainless steel bin, frame, enclosure panels.

14. Type 316L stainless steel contact parts.

15. Calculates and Displays the Production Rate (Bottles/Minute)

16. Saves and Stores Filling Programs for Future Use

17. Contamination Free Filling - Only the inside of the filling tube contacts the liquid. Ideal for high-purity applications

SPECIFICATION:

1. Capacity: 30-60 bottles/min

2. Power Supply: 2.5Kw, 110V/220V, 60Hz/Single phase

3. Air Consumption: 6 - 8 kg/cm² (87psi)

4. Dimension: 3100 x 1500 x 1750 mm ( LX W X H )

5. Net Weight: 850KG

6. Noise Level: 70~75 dB

7. Viscosity: 800 - 1500 cps

8. Applicable Bottle: 1- 30ml ( dia 16 to 25mm) (Height 30 - 150mm) plastic or glass containers

9. Mouth Opening (I/D): Ø10~15 mm (1/4” nozzle 6.5 mm), over Ø15 mm (Standard nozzle 13 mm)

OPTIONAL:

1. Liquid buffer/storage tanks.

2. Bottle buffering table

3. Safe door, door open, machine stop automatically.

4. Bottleneck holders

5. Rinser station before filling system station

6. Anti-drip filling nozzles for oils

7. Rejection station

8. Piston pump, Ceramic pump, and peristaltic pump as optional

MACHINE VIDEO:

APPLICATION:

Medicated oil, balm oil, massage oil, beard oil, tincture, Serum, CBD oil, hemp oil, cannabis oil, and cosmetic oil, hair oil, liquid drops, zinc supplement, eye drops, ear drops, saline nasal.

- 2024-10-25

- 2024-10-21

- 2024-09-24

- 2024-09-12

- 2024-09-12