Monoblock Roll On Essential Oil Droppper Bottle Filling Capping Machine

#MonoblockFillingMachine #FillingCappingMachine #RollOnFillingMachine #RollOnEssentialFillingMachine #MonoblockDropperFillingMachine

DESCRIPTION:

Automatic Monoblock Roll On bottle Filling and Capping machine are used for a wide variety of medical and cosmetic applications, from 1ml, 3ml, 6ml, 8ml, 9ml, 10ml, 12ml, 24ml, and 50ml from simple Perfume, Essential Oil, Massage Oil, Medical Oil, Medicated Oil, CBD Oil, THC Oil, Cannabis Oil, Sleep Oil. Compared to most liquid pharmaceutical products, the profit margins are often lower. This makes it important to be able to guarantee efficient and cost-effective processing for both pharmacy-only products and the over-the-counter (OTC) sector.

RVF Monoblock Roller On Bottle filling stoppering and capping machines provide the highest level of flexibility. Whether small batches or large batches, whether for product development and clinical studies or for commercial production, our solutions have a performance range of 30 to 80 units per minute (1800 - 4800 units per hour). These automatic lines are able to process containers made of glass as well as made of polymer.

At the same time, the RELIANCE RVF Monoblock Filler Capper Machine can be adapted quickly and flexibly – a key criterion, especially for CMOs and CDMOs. These lines for 1 ml to 10 ml filling and capping Perfume, Essential, and OTC Medicated Oil bottles are usually equipped with our innovative quick-connect technology. This enables a tool-free format change via the HMI.

FEEDING SYSTEM:

Our sorting unit allows the effective sorting of a wide variety of round oval and square objects. Permanently correct sorting is essential for the efficiency of the machine.

The RELIANCE sorting solution also makes it easy, safe, and completely move to feed all objects into the respective containment

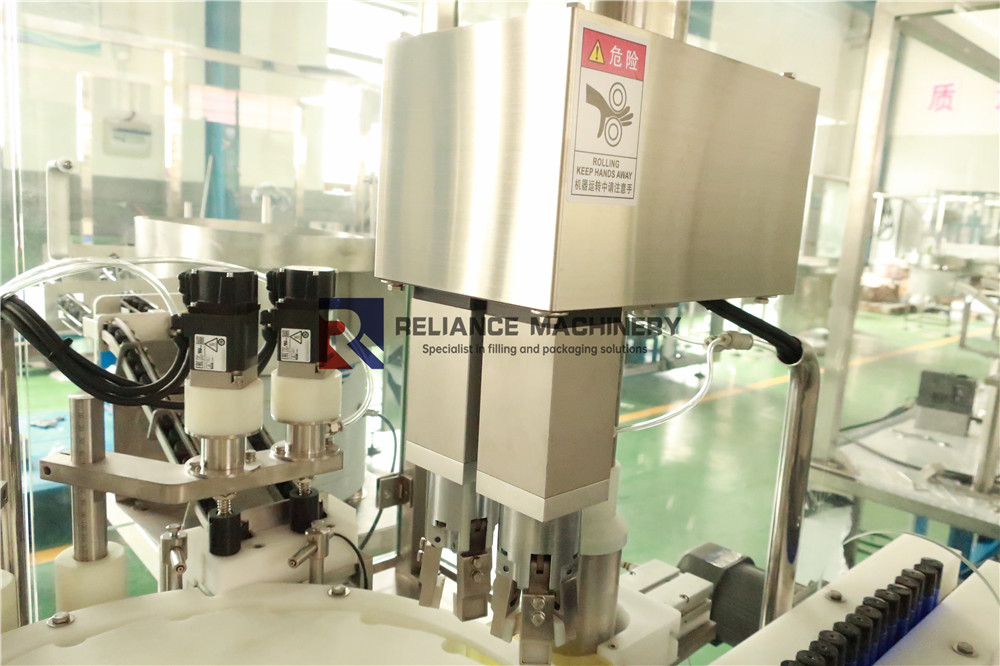

FILLING/DOSING SYSTEM:

The filling process is the heart of our system. For this, we use different technologies to be able to process a variety of thin to viscous products. Whether water-like/based liquids or oils or any solutions, we have the right system. When filling liquids, RELIANCE relies on proven filling technologies such as the rotary piston pump and peristaltic filling systems. Each of these filling lines can be used for one or more types of products.

Within these automatic filling machines, a wide variety of product-related tasks can definitely also be performed in the filling path. In particular, an air clean or Nitrogen module can be installed before filling. Whatever you need, RELIANCE adapts the filling processes to the needs of your product so that you do not have to compromise on quality. To meet the high requirements of the pharmaceutical industry, all the contact parts can be made of 316L stainless steel, and CIP system can be designed as requested.

CAPPING /CLOSING SYSTEM:

In the closing area, accurate sealing is one of the major challenges, particularly, when it comes to amber glass bottles. For many users of probiotic drop liquids, for example, it can become a major problem if the dropper caps are screwed on incorrectly or too tightly.

The RELIANCE tightening / Capping technology provides an efficient and economical solution for extremely accurate tightening, which also includes a monitoring step in which incorrectly tightened objects are detected and rejected.

We also have the right machine constellation for other closures for eye droppers or nasal applications with and without dip tube/pipette droppers; the same goes for push-on filter caps for preservative-free essential oil/ massage oil/ cannabis oil/ CBD Oil/ Hair Oil/ Medicated Oil.

FEATURE:

1. Diving type: Servo System or mechanical drive

2. 1 to 4 heads filling pump stations according to the speed required.

3. Piston pump, Ceramic pump, and peristaltic pump as optional

4. Application for different sizes and shapes of roll-on bottles by changing parts, such as round tube bottles, and square glass roll-on bottles, oval roll-on bottles.

5. Various speed settings of liquid filling, suited for small speeds 30 bottles/min, standard speed 60 bottles/min.

6. Easy to Clean and fast Changeover

7. High filling accuracy which can meet ±0.5% to ±1%.

8. Simple and quick tech mode setup.

9. Track full / track empty sensors tell the machine to stop or re-start

10. Bottle mouth holder design for special applications

11. Siemens PLC control with user-friendly operation, Touchscreen Display, and Easy to Navigate Menu

12. Motorized single-lane sanitary conveyor. customized conveyor lengths are available upon request.

13. Type 304 stainless steel bin, frame, enclosure panels.

14. Type 316L stainless steel contact parts.

15. Calculates and Displays the Production Rate (Bottles/Minute)

16. Saves and Stores Filling Programs for Future Use

17. Contamination Free Filling - Only the inside of the filling tube contacts the liquid. Ideal for high-purity applications

SPECIFICATION:

1. Capacity: 30-80 bottles/min

2. Power Supply: 2.5Kw, 110V/220V, 60Hz/Single phase

3. Air Consumption: 6 - 8 kg/cm² (87psi)

4. Dimension: 3100 x 1500 x 1750 mm ( LX W X H )

5. Net Weight: 850KG

6. Noise Level: 70~75 dB

7. Viscosity: 800 - 1500 cps

8. Applicable Bottle: 1- 30ml ( dia 16 to 25mm) (Height 30 - 150mm) plastic or glass containers

9. Mouth Opening (I/D): Ø10~15 mm (1/4” nozzle 6.5 mm), over Ø15 mm (Standard nozzle 13 mm)

|

No. |

High speed roll on bottle Filling Machine |

R-VF |

|

1 |

Application |

1ml-30ml |

|

2 |

Working condition |

220V 50Hz single phase |

|

3 |

Power |

1.3Kw |

|

4 |

Accuracy |

±0.5~1% |

|

5 |

Plugging |

≥99% |

|

6 |

Capping |

≥99% |

|

7 |

Speed control |

Adjusted by inverter |

|

8 |

Air pressure |

0.4-0.6Mpa |

|

9 |

Air consumption |

25-35L/min |

|

10 |

Noise |

≥70dB |

|

11 |

Weight |

Approx.300Kg |

|

12 |

Dimension |

2080×960×1480(mm) |

|

13 |

Capacity |

small speed > 30 bottles/min standard speed > 60 bottles/min |

OPTIONAL:

1. Liquid buffer/storage tanks.

2. Bottle buffering table

3. Safe door, door open, machine stop automatically.

4. Bottleneck holders

5. Rinser station before filling system station

6. Anti-drip filling nozzles for oils

7. Rejection station

8. Piston pump, Ceramic pump, and peristaltic pump as optional

MACHINE VIDEO:

APPLICATION:

Medicated oil, balm oil, massage oil, beard oil, tincture, serum, CBD oil, hemp oil, cannabis oil, and cosmetic oil, hair oil, liquid drops, zinc supplement, eye drops, ear drops, saline nasal.

- 2024-09-12

- 2024-09-12

- 2024-09-09

- 2024-08-13

- 2024-08-06